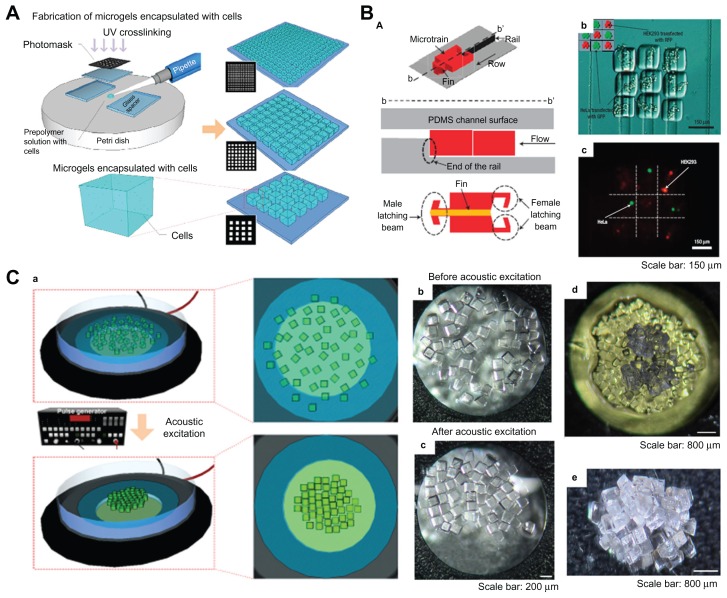

Figure 6.

Fabrication and assembly process for microgels via railed microfluidic and acoustic field. (A) Schematic of photolithography methods used to fabricate microgels.87 (B) Railed microfluidic assembly of microgels, (a) schematic of a microtrain, (b) assembled 3 × 3 matrix with two different living cells using cell-encapsulating thylene glycol diacrylate solution, and (c) fluorescent images of cell-encapsulating microgels. Scale bar 150 μm.23 (C) (a) Schematic of acoustic assembly of microgels; (b and c) before and after acoustic excitation, single-layer formation (200 μm × 200 μm microgels, scale bar 200 μm); (d) new microgels were introduced onto a single layer to generate a double-layered structure (scale bar 200 μm); (e) multilayered structure using layer-to-layer approach (scale bar 200 μm).24