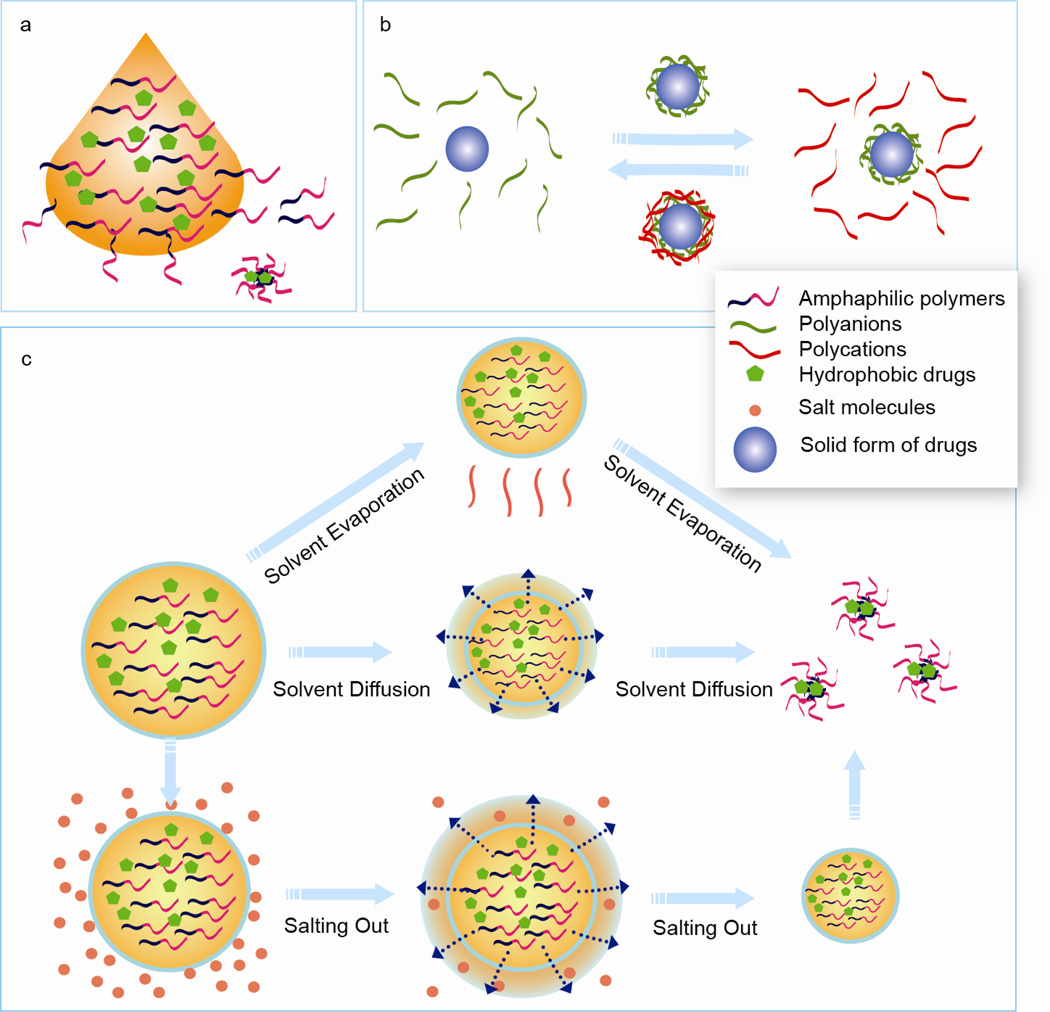

Figure 2.

Conventional nanoparticle fabrication methods. a) Nanoprecipitation. Polymer dissolved in organic solvent is added to an aqueous solution in a dropwise manner under constant agitation. Nanoparticles containing drugs form instantaneously as the polymer diffuses to the aqueous phase. b) Layer-by-Layer assembly. Solid form of drugs are used as the core. A polymer layer is first adsorbed onto the drug colloidal template by incubating in polymer solution and transferred to the oppsitely charged polymer solution for additional layering. This process is repeated until nanoparticles of desired sizes are formed. c) Emulsion-based two step methods. Emulsified oil-in-water droplets containing polymer and drugs are formed in the first step. In the second step, different methods are applied to remove the solvent and precipitate nanoparticles. Top pannel: Solvent evapoaration method. Solvents are gradually evaporated under vacuum and high pressure. Middle panel: Solvent diffusion method. The solvent used to prepare emulsion drops is partially miscible with water. When the emulsion droplets are diluted with water containing stablizer, organic solvent rapidly diffuses out from the droplets, leading to condensation of the materials within and formation of polymer nanoparticles. Bottom pannel: Salting out. The solvent used to prepare polymer and drug solution is totally miscible with water. Emulsification is conducted with aqueous phase containing high concentration of salt. The saturated aqueous phase prevents solvent from mixing with water. The emulsified droplets are then diluted in water. A sudden drop of salt concentration in continous phase causes extraction of organic solvent and precipiation of polymer drug nanoparticles.