Abstract

The objective of this study was to investigate the effect of particle surface coating with magnesium stearate on the aerosolization of dry powder inhaler formulations. Micronized salbutamol sulphate as a model drug was dry coated with magnesium stearate using a mechanofusion technique. The coating quality was characterized by X-ray photoelectron spectroscopy. Powder bulk and flow properties were assessed by bulk densities and shear cell measurements. The aerosol performance was studied by laser diffraction and supported by a twin-stage impinger. High degrees of coating coverage were achieved after mechanofusion, as measured by X-ray photoelectron spectroscopy. Concomitant significant increases occurred in powder bulk densities and in aerosol performance after coating. The apparent optimum performance corresponded with using 2% w/w magnesium stearate. In contrast, traditional blending resulted in no significant changes in either bulk or aerosolization behaviour compared to the untreated sample. It is believed that conventional low-shear blending provides insufficient energy levels to expose host micronized particle surfaces from agglomerates and to distribute guest coating material effectively for coating. A simple ultra-high-shear mechanical dry powder coating step was shown as highly effective in producing ultra-thin coatings on micronized powders and to substantially improve the powder aerosolization efficiency.

KEY WORDS: aerosolization, dry powder inhaler, magnesium stearate, mechanical dry powder coating, salbutamol sulphate

INTRODUCTION

In pulmonary drug delivery systems, only aerosolized fine drug particles (typically aerodynamic diameter ≤5 μm) can be efficiently delivered to the target sites in lungs (1). However, such fine powders generally have poor flow and poor aerosolization properties, which are main challenges for the formulation and manufacturing. These are because the fine cohesive particles tend to stick to each other, forming loose agglomerates due to the strong inter-particle cohesive forces arising from their small particle size and relative high surface area (2). In practice, in dry powder inhalers (DPIs), fine drug powder is generally mixed with coarse carriers (mostly lactose) to improve the flow. The formulation of these mixtures is also in order to ensure the consistency of aerosol performance (2). However, such carrier-based DPI formulations have disadvantages. Firstly, there may be unwanted chemical reactions between the carriers and certain drugs, for example, chemical reactions between lactose and some peptides or proteins (3). Moreover, those patients who are allergic to lactose and proteins may not be able to use the DPIs containing such substances (4). Furthermore, for high drug-dose treatments, the drug load of a single dose is substantially limited through the inclusion of carrier particles.

Modification of drug particle surface properties is of growing interest and may be an effective approach to improve the aerosolization of the drug particles by reducing intrinsic powder cohesion. Coating drug particles with anti-adhesive excipients, such as leucine, by spray drying has been demonstrated to improve the aerosol performance of dry powder inhaler formulations (5–7). Coating of leucine on the particles reduces the powder cohesion, which contributes to the improvement of aerosol performance (8,9). Coating micronized tobramycin powders with lipids by spray drying has also been demonstrated to improve the aerosol performance of DPIs (10). An improved aerosol performance was indicated after increasing corrugation of bovine serum albumin by spray drying. The improved aerosolization performance was achieved by decreasing their inter-particulate contact area, thus reducing inter-particle cohesive forces (11,12). Concerns on stability issues may arise for those drug particles generated by spray drying technique as it may form meta-stable amorphous part (13).

Mechanical dry coating techniques have gained increasing interests in order to modify bulk properties of powders by changing their surface characteristics through the intensive interaction between excipient (coating material) and drug powder (14). A solventless coating method has advantages over liquid-based one as it is generally simpler, safer, faster, more economical and more friendly to the environment (15). Previous studies have largely focused on modifying the surface of the lactose carrier (16). These studies report that substantial benefits to powder flow, fluidization and de-agglomeration performance of fine-milled lactose powders were obtained by mechanically coating surfaces with magnesium stearate (MgSt) (17). MgSt is chosen as the coating material in this study because it has been used to reduce the cohesion of powders via surface coating (16). MgSt is generally considered as safe when administered by inhalation (18) and has been approved to be used in commercial inhalation products such as Pulmicort® CFC-free metered dose inhaler and Foradil® Certihaler®, indicating its suitability for inhalation therapies (19). In a preliminary study, model drug powders were mechanically dry coated via a mechanofusion approach with MgSt (20). A substantial improvement in the aerosolization behaviour was shown after coating; however, the relationship between coating quality and powder aerosolization was not probed. In this study, a model micronized drug powder, salbutamol sulphate, was dry coated with a range of levels of MgSt using a mechanofusion technique. We investigated if it was possible to characterize the coating extent on such fine and irregular particles and then examined the coating effect on interactions between MgSt and micronized drug particles on the aerosol performance.

MATERIALS AND METHODS

Materials

The following materials were obtained: MgSt from Mallinckrodt Baker Inc, Phillipsburg, New Jersey, USA; micronized salbutamol sulphate (SS) from Cambrex Profarmaco, Milan, Italy; HPLC-grade ethanol from Scharlau Chemie S.A., Barcelona, Spain.

Methods

Intensive Mechanical Dry Coating

Drug powders were coated with MgSt in a mechanofusion system equipped with a Nobilta process module (AMS-Mini, Hosokawa Micron Corporation, Osaka, Japan). SS at a scale of 10 g batch size was combined with 0.5%, 2%, 5% and 10% w/w MgSt, and then the powder was introduced into the Nobilta process module. Mechanofusion processing was carried out by slowly ramping up the rotor speed to a peak of 5,000 rpm, and this was then maintained for 10 min, as previously described (21). Circulated cold water was passed through the water jacket, which prevented bulk module temperatures exceeding 25°C.

Particle Size Analysis

A Malvern Mastersizer® S (Malvern Instruments, Worcestershire, UK) with a small volume measuring cell (150 ml) was used to measure particle size distributions of powders using 300 RF lens. The dispersant used was a drug-saturated solution of cyclohexane with 0.5% (w/v) Span 80 (20). The D50 (diameter at 50% undersize), D10 (diameter at 10% undersize) and D90 (diameter at 90% undersize) were recorded.

XPS

An X-ray photoelectron spectroscopy (XPS) analysis method was applied to characterize quantitatively the extent of coverage of MgSt on the SS particle surfaces. An AXIS HSi Spectrometer with a monochromated Al Kα source (Kratos Analytical Ltd., Manchester, UK) was used to determine the spectrum. The details of XPS measurement were described previously (22). Briefly, a reference binding energy of 285.0 eV was used for the aliphatic hydrocarbon C 1s component. Survey spectra (320 eV pass energy) using sensitivity factors provided by the manufacturer were used for the calculation of elemental composition. High-resolution spectra of each peak were recorded at 40 eV pass energy with a peak width of typically 1.0–1.1 eV.

Particulate Interactions by Shear Cell Test

A Freeman FT4 powder rheometer system (Freeman Technology, Worcestershire, UK) was used in its shear module configuration to characterize aspects of the inter-particle interactions and powder flow. Briefly, the instrument measures the powder shear stress at a given consolidating normal stress. Schwedes (23) provided a full description of powder shear cell testing. Shear stress was measured at normal stresses of 7, 6, 5, 4 and 3 kPa. The yield loci were constructed from the shear stresses. The parameter “cohesion” was calculated by extrapolating the yield loci to a zero normal stress at the intercept. In general, higher cohesion values are considered to correspond to higher cohesive inter-particle forces. Standard Mohrs circle constructions provide the unconfined yield strength (σc) and major principle stress (σ1). The flow function (ffc) is used as an indicator of powder flow which is defined as the ratio of major principle stress to the unconfined yield strength. A greater flow function value generally represents better powder flow.

Powder Bulk Densities

Both the poured (ρp) and tapped (ρt) densities were measured. Powders were poured through a fixed-height funnel into a 10-ml measuring cylinder. Powders were tapped using an automatic tapper (AUTOTAP™, Quantachrome Instruments, Boynton Beach, USA) for 1,250 taps. Four replicates were performed for each measurement, and the results were averaged.

Powder De-agglomeration by Laser Diffraction

An online aerosol particle measurement system (Spraytec, Malvern Instruments, Worcestershire, UK) was used to evaluate powder de-agglomeration behaviour in real time, which provides geometric particle sizes rather than aerodynamic sizes, but is nonetheless considered a useful screening approach (24). Each powder (10 mg) was loaded into size 3 hydroxypropyl methylcellulose (HPMC) capsules (Capsugel, Peapack, New Jersey, USA) and placed in a Monodose inhaler device (Miat S.p.A., Milan, Italy). Powders were aerosolized from the device into the Spraytec inhaler module for 4 s at a flow rate of 60 l/min (calibrated by a TSI 4000 series flow meter, TSI, Shoreview, Minnesota, USA). Before aerosolization, each end of the capsule was punctured by pins to create holes. During the aerosolization, powders were released from the inhaler device through these holes as the capsule spins. The size distributions and the percentage by volume of fine particles (smaller than 6.3 μm) over the total load were calculated using the Spraytec software. The fine particle size of 6.3 μm is chosen here to provide an analogue of the cut-off diameter of twin-stage impinger. But it should be noted that laser diffraction measurement provides information of volumetric diameter while twin-stage impinger offers information of aerodynamic diameter.

In Vitro Aerosol Performance

A twin-stage impinger was employed to provide a complimentary aerodynamic alternative measurement to the laser diffraction, of the in vitro aerosol from the powder formulations (TSI, Apparatus A, British Pharmacopoeia, 2008). Milli Q water was used to collect drug powders. The airflow passing the TSI was adjusted to 60 l/min (HCP5, Copley, Nottingham, UK) at the mouthpiece. The cut-off aerodynamic diameter between stage 1 and 2 is 6.3 μm at the current operation condition (25). SS powder (10 mg) was weighed into HPMC capsules (size 3, Capsugel, Peapack, New Jersey, USA). Three individual capsules were aerosolized to each TSI from a Monodose inhaler device (Miat S.p.A., Milan, Italy) for 4 s (n = 3). All TSI measurements were performed in an air-conditioned room (20 ± 2°C, 50 ± 10% relative humidity). A validated ultraviolet spectroscopy method was used to detect the content of SS in each stage (20). Fine particle fraction (FPF) in this study was calculated as the ratio between the mass of the drug deposited in stage two and emitted mass. Emitted dose (ED) was defined as the ratio between the mass of the drug recovered outside the inhaler device and total load. Fine particle dose (FPD) is defined as the mass of drug powder deposits in the second stage.

Statistical Analysis

Analysis of variance (Tukey's post hoc analysis, p value of 0.05, SPSS, version 15.0.0, SPSS Inc., Chicago, USA) was used for statistical analysis.

RESULTS AND DISCUSSIONS

Particle Size Distribution

The primary particle size distribution results for SS samples are listed in Table I. There was no significant difference in D50 value between the untreated and the mixed samples (p > 0.05). Relatively small decreases in D50 were observed after mechanofusion. Given the SS particles experienced high-shear processing during the mechanofusion, this could be due to a slight attrition or alternatively breakage of strong bonding between the primary particles that standard particle size preparation methodology is insufficient to achieve (20). These similarities in results indicated that if there were any changes in powder bulk behaviours for the mechanofused SS powders, it should not be attributed to any substantial size enlargement or granulation effect.

Table I.

Particle Size Distributions of SS Samples Measured by Mastersizer® (mean ± SD, n = 3)

| D 10 (μm) | D 50 (μm) | D 90 (μm) | |

|---|---|---|---|

| Untreated | 0.6 ± 0.1 | 3.3 ± 0.1 | 7.8 ± 0.0 |

| Mixed 2% | 0.6 ± 0.1 | 3.2 ± 0.1 | 8.3 ± 0.1 |

| Mechanofused 0.5% | 0.7 ± 0.1 | 2.6 ± 0.1 | 6.8 ± 0.1 |

| Mechanofused 2% | 0.8 ± 0.0 | 2.7 ± 0.0 | 6.8 ± 0.0 |

| Mechanofused 5% | 0.7 ± 0.1 | 2.6 ± 0.1 | 6.9 ± 0.0 |

| Mechanofused 10% | 0.7 ± 0.1 | 2.7 ± 0.1 | 7.5 ± 0.0 |

D 10 diameter at 10% undersize, D 50 diameter at 50% undersize, D 90 diameter at 90% undersize

XPS

Surface chemical information of SS samples is listed in Table II. Since XPS detects chemical properties of the top 5–10 nm of the subject surface, the chemical properties measured here represent the outmost surface of the particles. There was no “Mg” detected for the untreated SS sample, and no “N” and “S” were detected for the pure MgSt sample, indicating that the “Mg” signal is exclusively from MgSt while “N” and “S” are exclusively from pure SS. The 2% mechanofused particle surfaces exhibited a much higher concentration of “Mg” and much lower concentrations of “N” and “S” than on the 2% mixed surfaces.

Table II.

Elemental Compositions of the Particle Surface of the Powders Measured by XPS. Listed Are Atomic Concentrations Relative to the Total Concentration of C (atomic ratios X/C)

| Sample | Elemental composition | |||

|---|---|---|---|---|

| O | N | S | Mg | |

| SS untreated | 0.375 | 0.085 | 0.038 | – |

| MgSt untreated | 0.099 | – | – | 0.028 |

| Mixed 2% | 0.324 | 0.068 | 0.030 | 0.010 |

| Mechanofused 0.5% | 0.292 | 0.063 | 0.029 | 0.007 |

| Mechanofused 2% | 0.181 | 0.03 | 0.014 | 0.017 |

| Mechanofused 5% | 0.138 | 0.011 | 0.006 | 0.021 |

| Mechanofused 10% | 0.124 | 0.007 | 0.004 | 0.024 |

Concentrations of “Mg” on the mechanofused SS surfaces increased while those of “N” and “S” decreased with increases in MgSt content. After mechanofusion with 10% MgSt, the powder surface gave values of atomic ratio “Mg/C” = 0.024, “N/C” = 0.007 and “S/C” = 0.004, which was close to the composition of the pure MgSt. These data indicated that after mechanofusion, the micronized SS particle surfaces were extensively coated with MgSt and will effectively appear from their exterior to comprise a form of MgSt. These data quantitatively support the concept that mechanofusion provides a coating with a greater extent of coverage of MgSt compared with conventional blending processes. It is proposed that the high energy input during the mechanofusion process is more effective at breaking the agglomerates of the micronized powders and exposing the surface of individual particles to the coating materials. Thus, MgSt can be coated on the individual particle surface during the mechanofusion. Furthermore, the greater shear and compression from mechanofusion is proposed to de-laminate the lamellar MgSt and effectively polish these soft materials over the SS surfaces. Further work will be required to optimize the quantitative outcome of this approach, and in addition, we believe it is required to understand the form of this MgSt, given that it is known to occur in a range of hydrates and forms (with proposed different physical effects on tribology) (26).

Shear Cell Test

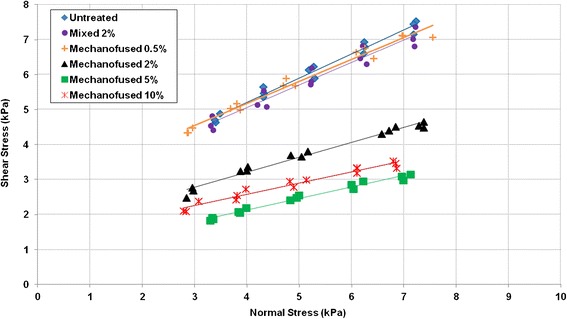

The shear cell results of SS samples are shown in Fig. 1 and Table III. It was observed that the shear stress values for the untreated, the mixed and the mechanofused 0.5% effectively overlapped. However, the shear stress values of the mechanofused samples with 2%, 5% and 10% MgSt were substantially lower. The mechanofused batch with 5% MgSt achieved the lowest shear stress values that indicated the lowest powder cohesion. The cohesion values obtained dramatically dropped 74% from 2.46 kPa for the untreated sample to the lowest 0.64 kPa for the mechanofused powder with 5% MgSt. Consequently, the powder flow in this context had been improved substantially after mechanofusion: as reflected also in the derived flow function results. There were no significant differences in cohesion and flow function values between the untreated sample and the mixed sample (p > 0.5).

Fig. 1.

Shear stress results of SS samples measured by the shear module of the FT4 powder rheometer

Table III.

Shear Results for SS Samples (mean ± SD, n = 3)

| Cohesion (kPa) | Flow function | |

|---|---|---|

| Untreated | 2.46 ± 0.10 | 1.91 ± 0.05 |

| Mixed 2% | 2.48 ± 0.17 | 1.92 ± 0.10 |

| Mechanofused 0.5% | 2.63 ± 0.13 | 1.73 ± 0.04 |

| Mechanofused 2% | 1.49 ± 0.11 | 3.13 ± 0.20 |

| Mechanofused 5% | 0.64 ± 0.03 | 6.70 ± 0.26 |

| Mechanofused 10% | 1.31 ± 0.14 | 3.48 ± 0.29 |

Bulk Densities

The data in Table IV show that there was no significant difference in tapped density value between the untreated and the mixed batches (p > 0.05). A slight increase in poured density was noticed after mixing. In contrast, substantial and significant increases in both poured and tapped densities were demonstrated after mechanofusion with MgSt, even only with 0.5% w/w of MgSt incorporated (p < 0.05). For example, the tapped density and poured density values increased 93.5% and 95.8%, respectively, from the untreated batch to the mechanofused batch with 2% w/w MgSt. Both poured and tapped densities for the mechanofused batches increased with an increase in MgSt concentration up to 2%. There were no significant differences in both poured and tapped density values between the 2%, 5% and 10% batches (p > 0.05).

Table IV.

Powder Bulk Densities of SS Samples (mean ± SD, n = 4)

| Poured density (g/ml) | Tapped density (g/ml) | |

|---|---|---|

| Untreated | 0.154 ± 0.016 | 0.284 ± 0.009 |

| Mixed 2% | 0.197 ± 0.011 | 0.290 ± 0.008 |

| Mechanofused 0.5% | 0.273 ± 0.011 | 0.504 ± 0.022 |

| Mechanofused 2% | 0.298 ± 0.014 | 0.556 ± 0.031 |

| Mechanofused 5% | 0.292 ± 0.016 | 0.562 ± 0.009 |

| Mechanofused 10% | 0.301 ± 0.013 | 0.571 ± 0.010 |

Powder De-agglomeration by Laser Diffraction

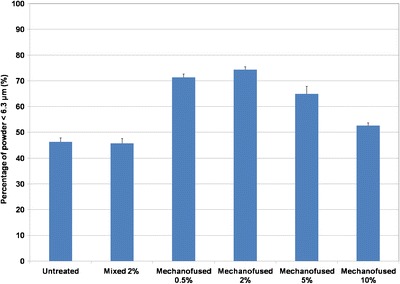

The powder de-agglomeration behaviour reflected by the size distributions after aerosolization from a Monodose inhaler device is shown in Fig. 2 and Table V. It should be noted that the size distribution measured here by a Spraytec is volumetric, not aerodynamic. As cohesive powders generally exhibit as agglomerates due to high inter-particulate cohesive forces, the size distribution data can either be of particles or agglomerates. There was no significant difference between the untreated and the mixed samples in the percentage of particles smaller than 6.3 μm (fine particle percentage) (p > 0.05). All mechanofused samples had significantly greater fine particle percentages than the untreated batch (p < 0.05). The mechanofused sample coated with 2% MgSt achieved the greatest fine particle percentage of 74.4%. These results indicated that agglomerates were more efficiently dispersed into inhalable particles after surface coating.

Fig. 2.

De-agglomeration behaviour of SS samples measured by Spraytec at a flow rate of 60 l/min (The data represent means, and the error bars represent standard deviations; n = 3)

Table V.

Size Distributions of SS Powders During the Aerosolization at Flow Rate of 60 l/min Measured by Spraytec (mean ± SD, n = 3)

| D 10 (μm) | D 50 (μm) | D 90 (μm) | |

|---|---|---|---|

| Untreated | 2.0 ± 0.1 | 7.0 ± 0.3 | 99.8 ± 10.0 |

| Mixed 2% | 2.0 ± 0.0 | 7.1 ± 0.4 | 118.1 ± 16.2 |

| Mechanofused 0.5% | 1.5 ± 0.1 | 3.9 ± 0.1 | 15.3 ± 3.3 |

| Mechanofused 2% | 1.3 ± 0.2 | 3.7 ± 0.0 | 14.3 ± 1.1 |

| Mechanofused 5% | 1.6 ± 0.1 | 4.6 ± 0.3 | 15.2 ± 1.5 |

| Mechanofused 10% | 1.8 ± 0.0 | 6.0 ± 0.2 | 20.0 ± 1.1 |

D 10 diameter at 10% undersize, D 50 diameter at 50% undersize, D 90 diameter at 90% undersize

There were no significant differences in D10, D50 and D90 values between the untreated and the mixed batch (p > 0.05). However, the D10, D50 and D90 values of all the mechanofused batches were substantially lower than those of the untreated sample. The D50 value reached the lowest of 3.7 μm after mechanofusion with 2% MgSt. This compares with a value of 2.7 μm obtained from the powder via Malvern Mastersizer wet dispersion and indicates a powder that is approaching a full level of de-agglomeration. Further increases in MgSt concentration resulted in increases in D50. These suggested that the aerosolization behaviour of the mechanofused powders achieves an optimal performance when coated with 2% MgSt.

The D90 values were substantially reduced from 99.8 μm for the untreated sample to 14.3 μm for the 2% mechanofused sample. These data indicate that large agglomerates existed during the aerosolization for the untreated sample due to the strong agglomerate strength. After mechanofusion, the agglomerate bonding forces were much weaker, and thus, more large agglomerates could be dispersed into small agglomerates or separate primary particles compared to the untreated SS powder.

In Vitro Performance

The in vitro aerosolization outcomes of SS samples are listed in Table VI. The untreated sample achieved an emitted dose value of 71.4%. The emitted dose values of the mechanofused samples were variable, but the mechanofused 2% batch achieved the highest value of 81%. These demonstrated that the Monodose inhaler device had high device emptying efficiency at a flow rate of 60 L/min (27). The powder fluidization and centrifugal forces generated during the air flow by both the device and the capsules within the device contributed to the efficient device emptying (17,28).

Table VI.

In Vitro Aerosolization Results of SS Samples Measured by TSI at Flow Rate of 60 l/min (mean ± SD, n = 3)

| FPD (mg) | FPF (%) | ED (%) | |

|---|---|---|---|

| Untreated | 10.2 ± 0.1 | 51.1 ± 2.9 | 71.4 ± 1.8 |

| Mixed 2% | 10.7 ± 0.4 | 54.1 ± 1.2 | 65.6 ± 1.4 |

| Mechanofused 0.5% | 15.4 ± 0.3 | 77.4 ± 1.3 | 66.3 ± 0.4 |

| Mechanofused 2% | 18.3 ± 0.1 | 75.4 ± 1.0 | 81.0 ± 0.7 |

| Mechanofused 5% | 13.7 ± 0.4 | 67.5 ± 2.1 | 67.4 ± 0.7 |

| Mechanofused 10% | 13.0 ± 0.5 | 65.2 ± 2.6 | 66.5 ± 0.9 |

FPD fine particle dose, FPF fine particle fraction, ED emitted dose

There was no difference in FPD between the untreated and the mixed batches (p > 0.05). All mechanofused powders had significantly greater FPD values than those of the untreated sample (p < 0.05). The FPD increased from 15.4 mg for the 0.5% mechanofused batch to 18.3 mg for the 2% mechanofused batch. However, further increases in MgSt concentration resulted in decreases in FPD. A similar trend was also demonstrated in FPF values. The FPF value reached the maximum when SS powder was mechanofused with 0.5% or 2% MgSt (there was no significant difference in FPF between the 0.5% and 2% batches, p > 0.05). These results indicated that the optimal aerosolization performance here could be achieved when the SS powders were mechanofused with 2% MgSt, which was in good agreement with those de-agglomeration results measured by Spraytec. Although an improved FPF with 0.5% MgSt suggests effective de-agglomeration once the powder is resuspended, it is suggested that this lower MgSt content is not as effective in facilitating the earlier stage of aerosolization, comprising fluidization from the powder bed, reflected by a relatively low ED value. Dry coating with 2% w/w of MgSt was indicated as optimal for aerosolization in this study; nevertheless, the concentration of MgSt can be adjusted according to the dose of APIs to avoid any possible concern on lung toxicity although MgSt is generally considered as safe for inhalation (18).

DISCUSSION

It was not surprising that the poured and tapped densities of the untreated micronized SS powder were relatively low, 0.154 and 0.284 g/ml, respectively, given their very fine particle sizes. For fine particles smaller than 10 μm, the inter-particle attractive forces can be as high as 4-fold of their gravitational forces (29). Such fine particles generally tend to form extensive open structure agglomerates under the relatively high attractive forces and exhibit very poor packing efficiency. However, both poured and tapped densities of the mechanofused samples were substantially higher, approaching a doubling in value compared to the untreated SS sample. These were attributed to the reduction in their powder cohesion, which was then quantified by the shear cell tests. The improvement in packing efficiency of the fine powders after surface coating has implications that it enables higher powder dose within the inhaler device, which may be advantageous or necessary for high-dose DPI formulations. It is interesting to note that such mechanofused powders with high bulk density are in distinct contrast to those dry powder inhaler formulations with low bulk density which have received a great deal of attention as being ideal for future inhaled products (30,31). However, low-bulk-density powders provide challenges requiring greater storage capacity, as well as generally being more fragile and susceptible to change via damage, and in general are more complex and expensive to produce (32).

The XPS results demonstrated that mechanofusion produced a high degree of coverage of MgSt coating on the micronized SS powder surfaces. This coating contributed to the reduction of the powder cohesion, improvement in powder packing and, thus, improvements in powder aerosolization performance, given the fact that no apparent size enlargement occurred (20). Quantitative measurement of surface roughness is very challenging at the scale and nature of these very fine particles. But, SEM images suggest that there is no substantial increase in surface roughness after mechanofusion with MgSt (20). A previous study reported that modification of surface chemistry has much greater impact than changing surface roughness on the flow properties of fine lactose particles (33). Hence, it is assumed that in this context, modification of surface chemistry may be more powerful than altering rugosity for micronized particles on aerosolization outcomes.

There were no differences found in powder bulk and aerosolization behaviour between the untreated and the mixed SS samples. This indicates that such substantial reduction in powder cohesion and improvements in powder bulk and aerosolization behaviour achieved by mechanofusion could not be achieved under similar conditions by conventional blending for the micronized powders. This is because the energy provided by conventional blending is insufficient to break powder agglomerates and to coat MgSt onto fine particle surfaces (21). Thus, it is not surprising that most relevant studies were focusing on coating the lactose carrier with MgSt (34,35) rather than coating micronized drug powders for dry powder inhaler formulations since an efficient coating device or technique is required for coating fine powders in this case.

The optimal concentration of the coating material, MgSt, for the mechanofusion of micronized SS powder was in the region of 2% w/w. When higher concentrations of MgSt were applied for coating such as 10% w/w, the de-agglomeration behaviour and in vitro aerosolization performance of the coated SS powders were not further improved but, in contrast, fell slightly. In a previous study, excessive MgSt resulted in multi-laminar layers with an increase in surface roughness (33). These rough sites on the particle surface were proposed to promote particle inter-locking which was then proposed to cause an increase in powder cohesion. Although XPS results showed further increases in the surface levels of MgSt when the concentration of MgSt was increased from 2% to 10%, this does not necessarily correspond to an increase in surface coverage but might actually indicate an increase in coating thickness. Previous results indicated that XPS probed deeper than the mono-laminar coating layer of MgSt on fine mechanofused lactose particles. Thus, a part of the chemical information collected by XPS for the mechanofused particles was not only from the coating layer but also from chemical information of the drug particle beneath the coating layer (22). Moreover, excessive MgSt also may exist as separate MgSt particles in the form of soft flake shapes, which could also contribute to the slight increase in powder cohesion.

CONCLUSIONS

Results presented in this study provide evidence that improvement in powder bulk behaviour and aerosol performance in a micronized drug powder, salbutamol sulphate, can be achieved through mechanical surface coating with a traditional tablet lubricant, magnesium stearate. The coated SS powders exhibited much higher poured and tapped densities compared to the untreated batch, which facilitates the design of high-dose inhaler formulations. Despite increased density, very substantial improvements in aerosol performance were demonstrated for the coated SS powders. Such improvements were attributed to the reduction in powder cohesion after surface coating. There were no significant differences demonstrated between the untreated and the blended SS sample because the energy input from a traditional blending was insufficient to break agglomerates of the micronized SS powder and thus was unable to coat individual particle surfaces. Coating with 2% MgSt was shown to achieve the greatest improvement in aerosolization performance for the micronized SS powder in this study. It is proposed that the aerosolization behaviour was associated with formation of at least a mono-laminar coating layer formed by MgSt at estimated optimal concentrations on the particle surface. Further increases in the concentration of coating material appear to result in a decline in their aerosolization performance, which result from excessive MgSt presented. The ability to characterize this ultra-thin coating, shown here by XPS, enables investigations of the fundamental understanding of the relationship between coating and aerosolization.

ACKNOWLEDGMENTS

Qi (Tony) Zhou acknowledges the financial support of Postgraduate Publications Award from Monash University. Miat S.p.A and Capsugel Australia are acknowledged for kind donations of Monodose inhalers and HPMC capsules, respectively.

Contributor Information

Qi (Tony) Zhou, Email: tonygoe1980@hotmail.com.

David A. V. Morton, Phone: +61-3-99039523, FAX: +61-3-99039583, Email: david.morton@monash.edu

REFERENCES

- 1.Timsina MP, Martin GP, Marriott C, Ganderton D, Yianneskis M. Drug-delivery to the respiratory-tract using dry powder inhalers. Int J Pharm. 1994;101(1–2):1–13. doi: 10.1016/0378-5173(94)90070-1. [DOI] [Google Scholar]

- 2.Chan HK, Chew NYK. Novel alternative methods for the delivery of drugs for the treatment of asthma. Adv Drug Deliv Rev. 2003;55(7):793–805. doi: 10.1016/S0169-409X(03)00078-4. [DOI] [PubMed] [Google Scholar]

- 3.Patton JS, Platz RM. Penetration enhancement for polypeptides through epithelia. D. Routes of delivery—case-studies. 2. Pulmonary delivery of peptides and proteins for systemic action. Adv Drug Deliv Rev. 1992;8(2–3):179–196. doi: 10.1016/0169-409X(92)90002-8. [DOI] [Google Scholar]

- 4.Kretchme N, Faber HK. Lactose intolerance. Nutr Rev. 1972;30(11):260. [Google Scholar]

- 5.Najafabadi AR, Gilani K, Barghi M, Rafiee-Tehrani M. The effect of vehicle on physical properties and aerosolisation behaviour of disodium cromoglycate microparticles spray dried alone or with L-leucine. Int J Pharm. 2004;285(1–2):97–108. doi: 10.1016/j.ijpharm.2004.07.027. [DOI] [PubMed] [Google Scholar]

- 6.Rabbani NR, Seville PC. The influence of formulation components on the aerosolisation properties of spray-dried powders. J Control Release. 2005;110(1):130–140. doi: 10.1016/j.jconrel.2005.09.004. [DOI] [PubMed] [Google Scholar]

- 7.Raula J, Laehde A, Kauppinen EI. A novel gas phase method for the combined synthesis and coating of pharmaceutical particles. Pharm Res. 2008;25(1):242–245. doi: 10.1007/s11095-007-9464-4. [DOI] [PubMed] [Google Scholar]

- 8.Chew NYK, Shekunov BY, Tong HHY, Chow AHL, Savage C, Wu J, et al. Effect of amino acids on the dispersion of disodium cromoglycate powders. J Pharm Sci. 2005;94(10):2289–2300. doi: 10.1002/jps.20426. [DOI] [PubMed] [Google Scholar]

- 9.Sou T, Orlando L, McIntosh MP, Kaminskas LM, Morton DAV. Investigating the interactions of amino acid components on a mannitol-based spray-dried powder formulation for pulmonary delivery: a design of experiment approach. Int J Pharm. 2011;421(2):220–229. doi: 10.1016/j.ijpharm.2011.09.018. [DOI] [PubMed] [Google Scholar]

- 10.Pilcer G, Sebti T, Amighi K. Formulation and characterization of lipid-coated tobramycin particles for dry powder inhalation. Pharm Res. 2006;23(5):931–940. doi: 10.1007/s11095-006-9789-4. [DOI] [PubMed] [Google Scholar]

- 11.Chew NYK, Chan HK. Use of solid corrugated particles to enhance powder aerosol performance. Pharm Res. 2001;18(11):1570–1577. doi: 10.1023/A:1013082531394. [DOI] [PubMed] [Google Scholar]

- 12.Adi H, Traini D, Chan HK, Young PM. The influence of drug morphology on the aerosolisation efficiency of dry powder inhaler formulations. J Pharm Sci. 2008;97(7):2780–2788. doi: 10.1002/jps.21195. [DOI] [PubMed] [Google Scholar]

- 13.Chow AHL, Tong HHY, Chattopadhyay P, Shekunov BY. Particle engineering for pulmonary drug delivery. Pharm Res. 2007;24(3):411–437. doi: 10.1007/s11095-006-9174-3. [DOI] [PubMed] [Google Scholar]

- 14.Pfeffer R, Dave RN, Wei D, Ramlakhan M. Synthesis of engineered particulates with tailored properties using dry particle coating. Powder Technol. 2001;117(1–2):40–67. doi: 10.1016/S0032-5910(01)00314-X. [DOI] [Google Scholar]

- 15.Bose S, Bogner RH. Solventless pharmaceutical coating processes: a review. Pharm Dev Technol. 2007;12(2):115–131. doi: 10.1080/10837450701212479. [DOI] [PubMed] [Google Scholar]

- 16.Zhou Q, Morton DAV. Drug-lactose binding aspects in adhesive mixtures: controlling performance in dry powder inhaler formulations by altering lactose carrier surfaces. Adv Drug Deliv Rev. 2012;64(3):275–284. doi: 10.1016/j.addr.2011.07.002. [DOI] [PubMed] [Google Scholar]

- 17.Zhou QT, Armstrong B, Larson I, Stewart PJ, Morton DAV. Understanding the influence of powder flowability, fluidization and de-agglomeration characteristics on the aerosolization of pharmaceutical model powders. Eur J Pharm Sci. 2010;40(5):412–421. doi: 10.1016/j.ejps.2010.04.012. [DOI] [PubMed] [Google Scholar]

- 18.Rowe RC, Sheskey PJ, Quinn ME. Handbook of pharmaceutical excipients. 6. London: Pharmaceutical Press; 2009. p. 434. [Google Scholar]

- 19.Pilcer G, Amighi K. Formulation strategy and use of excipients in pulmonary drug delivery. Int J Pharm. 2010;392(1–2):1–19. doi: 10.1016/j.ijpharm.2010.03.017. [DOI] [PubMed] [Google Scholar]

- 20.Zhou QT, Qu L, Larson I, Stewart PJ, Morton DAV. Improving aerosolization of drug powders by reducing powder intrinsic cohesion via a mechanical dry coating approach. Int J Pharm. 2010;394(1–2):50–59. doi: 10.1016/j.ijpharm.2010.04.032. [DOI] [PubMed] [Google Scholar]

- 21.Zhou QT, Armstrong B, Larson I, Stewart PJ, Morton DAV. Improving powder flow properties of a cohesive lactose monohydrate powder by intensive mechanical dry coating. J Pharm Sci. 2010;99(2):969–981. doi: 10.1002/jps.21885. [DOI] [PubMed] [Google Scholar]

- 22.Zhou QT, Denman JA, Gengenbach T, Das S, Qu L, Zhang H, et al. Characterization of the surface properties of a model pharmaceutical fine powder modified with a pharmaceutical lubricant to improve flow via a mechanical dry coating approach. J Pharm Sci. 2011;100(8):3421–3430. doi: 10.1002/jps.22547. [DOI] [PubMed] [Google Scholar]

- 23.Schwedes J. Review on tester for measuring flow properties of bulk solids. Granul Matter. 2001;5:1–43. doi: 10.1007/s10035-002-0124-4. [DOI] [Google Scholar]

- 24.Marriott C, MacRitchie HB, Zeng XM, Martin GP. Development of a laser diffraction method for the determination of the particle size of aerosolised powder formulations. Int J Pharm. 2006;326(1–2):39–49. doi: 10.1016/j.ijpharm.2006.07.021. [DOI] [PubMed] [Google Scholar]

- 25.Srichana T, Martin GP, Marriott C. A human oral-throat cast integrated with a twin-stage impinger for evaluation of dry powder inhalers. J Pharm Pharmacol. 2000;52(7):771–778. doi: 10.1211/0022357001774624. [DOI] [PubMed] [Google Scholar]

- 26.Miller TA, York P. Pharmaceutical tablet lubrication. Int J Pharm. 1988;41(1–2):1–19. doi: 10.1016/0378-5173(88)90130-5. [DOI] [Google Scholar]

- 27.Kippax P, Morton DAV. Aerosolization analysis. Drug Deliv Technol. 2008;8(1):53–58. [Google Scholar]

- 28.Coates MS, Fletcher DF, Chan HK, Raper JA. The role of capsule on the performance of a dry powder inhaler using computational and experimental analyses. Pharm Res. 2005;22(6):923–932. doi: 10.1007/s11095-005-4587-y. [DOI] [PubMed] [Google Scholar]

- 29.Castellanos A. The relationship between attractive interparticle forces and bulk behaviour in dry and uncharged fine powders. Adv Phys. 2005;54(4):263–376. doi: 10.1080/17461390500402657. [DOI] [Google Scholar]

- 30.Edwards DA, Hanes J, Caponetti G, Hrkach J, BenJebria A, Eskew ML, et al. Large porous particles for pulmonary drug delivery. Science. 1997;276(5320):1868–1871. doi: 10.1126/science.276.5320.1868. [DOI] [PubMed] [Google Scholar]

- 31.Ikegami K, Kawashima Y, Takeuchi H, Yamamoto H, Mimura K, Mamose D, et al. A new agglomerated KSR-592 beta-form crystal system for dry powder inhalation formulation to improve inhalation performance in vitro and in vivo. J Control Release. 2003;88(1):23–33. doi: 10.1016/S0168-3659(02)00460-1. [DOI] [PubMed] [Google Scholar]

- 32.Telko MJ, Hickey AJ. Dry powder inhaler formulation. Respir Care. 2005;50(9):1209–1227. [PubMed] [Google Scholar]

- 33.Zhou QT, Qu L, Gengenbach T, Denman JA, Larson I, Stewart PJ, et al. Investigation of the extent of surface coating via mechanofusion with varying additive levels and the influences on bulk powder flow properties. Int J Pharm. 2011;413(1–2):36–43. doi: 10.1016/j.ijpharm.2011.04.014. [DOI] [PubMed] [Google Scholar]

- 34.Iida K, Hayakawa Y, Okamoto H, Danjo K, Luenberger H. Effect of surface layering time of lactose carrier particles on dry powder inhalation properties of salbutamol sulfate. Chem Pharm Bull. 2004;52(3):350–353. doi: 10.1248/cpb.52.350. [DOI] [PubMed] [Google Scholar]

- 35.Young PM, Cocconi D, Colombo P, Bettini R, Price R, Steele DF, et al. Characterization of a surface modified dry powder inhalation carrier prepared by “particle smoothing”. J Pharm Pharmacol. 2002;54(10):1339–1344. doi: 10.1211/002235702760345400. [DOI] [PubMed] [Google Scholar]