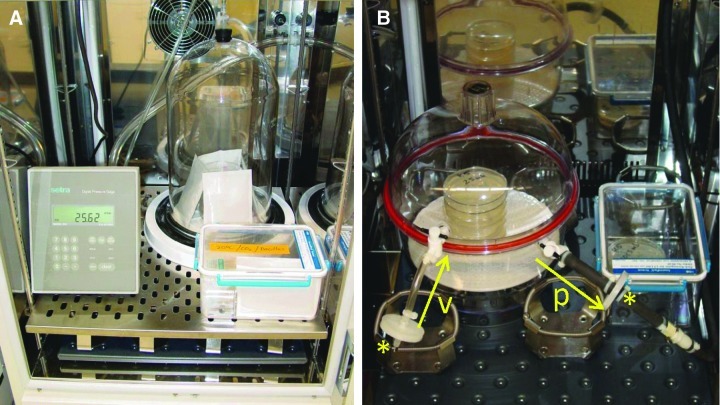

FIG. 1.

Hypobaric chambers used for creating low-pressure conditions reported in Tables 2, 3, and 6, and Figs. 2, 3, and 4. (A) One system was composed of a single glass bell jar attached to a high-density polyethylene stage through which vent holes permitted the connection to external pumps and controllers (model PU-842, KNF, Neuberger, Trenton NJ, USA). For anoxic conditions, AnaeroPack (Remel, Thermo Fisher Scientific, Chicago, IL, USA) sachets were placed around each stack of up to six Petri dishes of TSA or SSA media. (B) A second hypobaric system was developed to replace the single glass bell jar system in which two separate hypobaric chambers were maintained in separate microbial incubators. The newer hypobaric chambers were composed of clear polycarbonate desiccators (model #08-642-7, Thermo-Fisher Scientific, Rochester, NY, USA) connected to two separate KNF pump/controllers placed on the outsides of the microbial incubators. For each unit, in-line 0.22 μm filters (*) were used on the vent line (v) and the pump line (p) to prevent the introduction of room air into the hypobaric chamber during normal operations. Arrows designate the airflow into and out of the hypobaric desiccator system. Color images available online at www.liebertonline.com/ast