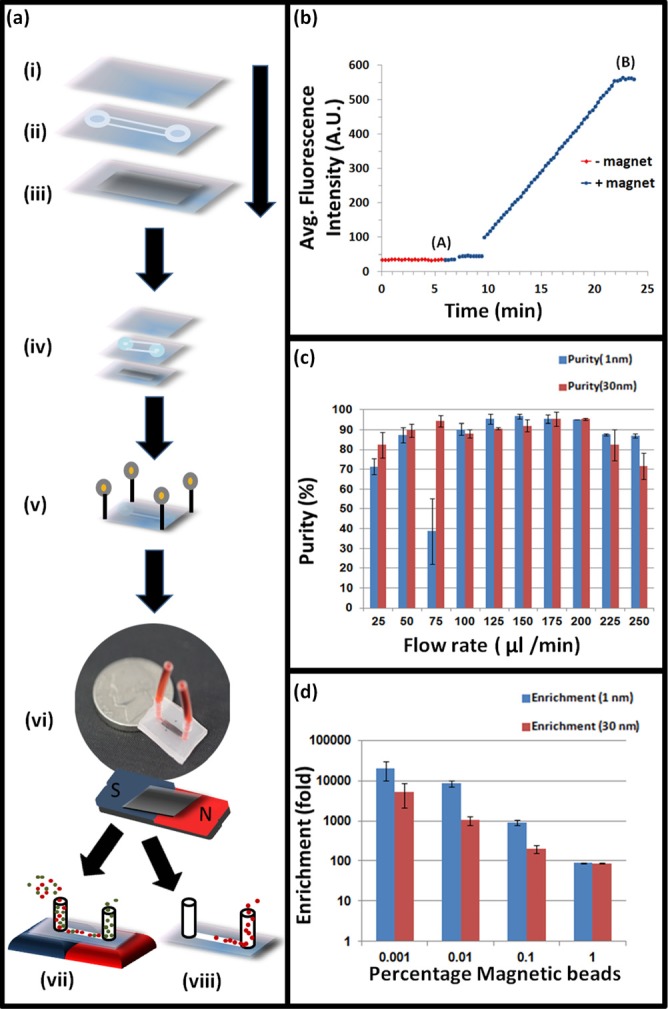

Figure 3.

Fabrication of NSMT integrated microfluidic device. (a) Steps of fabrication and modes of operation. The device consists of three PO layers: a top layer (i), a channel layer (ii), and bottom layer (iii) containing the NSMT. The top layer is single sheet of PO to seal the channel. Channels were designed using CAD software and cut in PO using a laser cutter before the film was shrunk. To create the NSMT layer, 1 nm or 30 nm nickel was sputter coated on pre-stressed PO. The three layers were then aligned (iv) and secured using 0.4 mm pins (v). Layers were then heated to 155 °C to bond them together and form the device. The extraction mode is indicated in vii. The collection mode is indicated in viii. (b) Indicates the variation of fluorescence vs. time in extraction mode. Fluorescence was recorded while flowing 1 μm fluorescent magnetic beads through the microfluidic device. (c) Purity vs. flow rate for 1% magnetic bead and 99% polystyrene bead mixture. (d) Variation of enrichment vs. % magnetic beads.