Table 1.

Optimization of the reaction conditionsa

| entry | time (min) | temp.(°C) | solvent | ratio 4:5:6 | catalyst | yield 7b (%) | |

|---|---|---|---|---|---|---|---|

| step 1 | step 1 | step 1 | step 2 | ||||

| 1 | 15 | 60 | Et3N | MeCN | 1:1.05:1.1 | 2 mol % PdCl2(PPh3)2 1 mol % CuI | 51 |

| 2 | 15 | 60 | Et3N | MeCN | 1:1.05:1.1 | 2 mol % Pd(PPh3)4 1 mol % CuI | 23 |

| 3 | 15 | 60 | Et3N | MeCN | 1:1.05:1.1 | 2 mol % Pd(dppe)2 1 mol % CuI | 10 |

| 4 | 15 | 60 | Et3N | MeCN | 1:1.05:1.1 | 2 mol % Pd(OAc)2 4 mol % PPh3 1 mol % CuI | 6 |

| 5 | 15 | 60 | Et3N | MeCN | 1:1.05:1.0 | 2 mol % PdCl2(PPh3)2 1 mol % CuI | 53 |

| 6 | 15 | 60 | iPr2NH | MeCN | 1:1.05:1.0 | 2 mol % PdCl2(PPh3)2 1 mol % CuI | 50 |

| 7 | 15 | 60 | Et3N | DMF | 1:1.05:1.0 | 2 mol % PdCl2(PPh3)2 1 mol % CuI | 34 |

| 8 | 15 | 60 | Et3N | THF | 1:1.05:1.0 | 2 mol % PdCl2(PPh3)2 1 mol % CuI | 29 |

| 9 | 15 | 60 | Et3N | Toluene | 1:1.05:1.0 | 2 mol % PdCl2(PPh3)2 1 mol % CuI | 15 |

| 10 | 25 | 80 | Et3N | MeCN | 1:1.05:1.0 | 2 mol % PdCl2(PPh3)2 1 mol % CuI | 20 |

| 11c | 15 | 25 | Et3N | MeCN | 1:1.05:1.0 | 2 mol % PdCl2(PPh3)2 1 mol % CuI | 53 |

| 12 | 30 | 25 | Et3N | MeCN | 1:1.05:1.0 | 2 mol % PdCl2(PPh3)2 1 mol % CuI | 73 |

| 13 | 30 | 25 | Et3N | MeCN | 1:1.05:1.0 | 3 mol % PdCl2(PPh3)2 2 mol % CuI | 86 |

| 14d | 30 | 25 | NMM/Et3N | MeCN | 1:1.2:1.0 | 3 mol % PdCl2(PPh3)2 2 mol % CuI | 89 |

| 15e | 30 | 25 | THF/Et3N | MeCN | 1:1.2:1.0 | 3 mol % PdCl2(PPh3)2 2 mol % CuI | 96 |

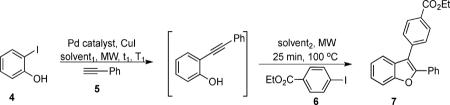

Unless otherwise noted, all of the reactions were carried out under microwave irradiation on a 1.0 mmol scale in microwave-resistant vials.

Isolated yields after column chromatography.

When the first step of the reaction was carried out at 25 °C, much cleaner reaction mixtures were obtained than at 60 °C.

0.5 mL of N-methylmorpholine (NMM)/1.5 mL of Et3N using anhydrous solvents under argon.

0.5 mL of THF/1.0 mL of Et3N, and CuI were added as a solution in 0.5 mL of Et3N using anhydrous solvents under argon.