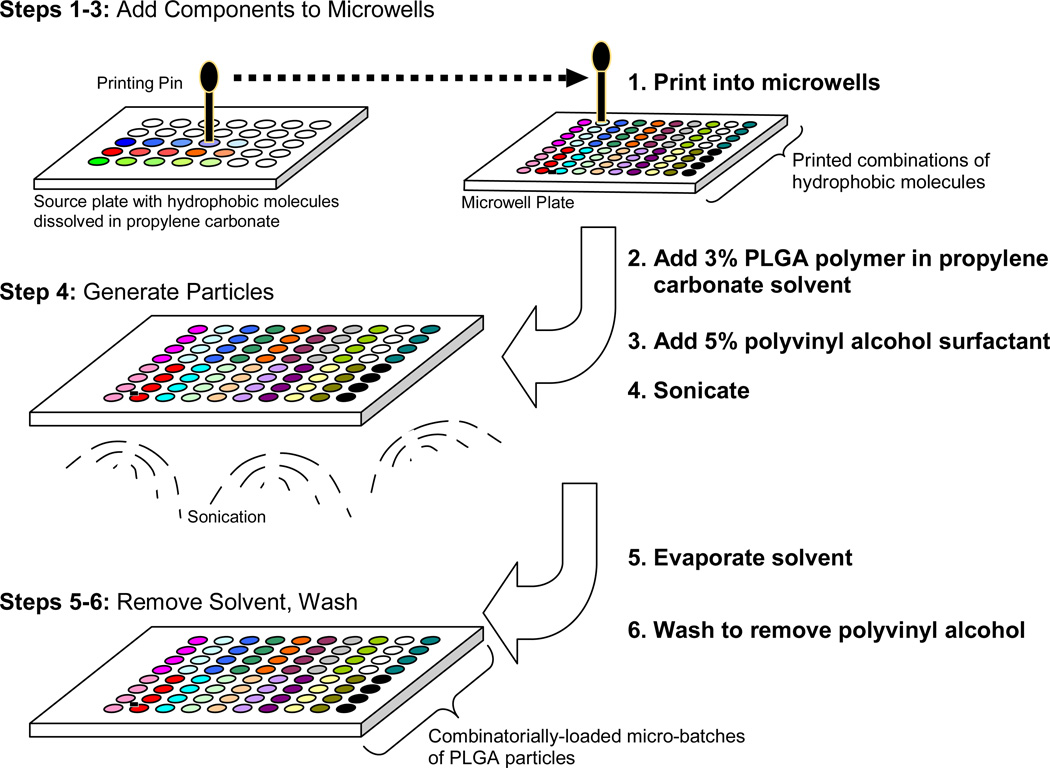

Figure 1. Parallel Particle Production.

Microparticles of poly(lactide-co-glycolide) (PLGA) co-encapsulating multiple hydrophobic components are generated using oil-in-water emulsification in a multi-well polystyrene plate serving as a bank of chambers in which hundreds of particle “micro-batches” are simultaneously generated. Fluorescent dyes are encapsulated as proof of principle, serving as a proxy combination drug formulation. The parallel particle production (PPP) method consists of: Step 1–3.) Dip-pen miniarrayer is programmed to combinatorially add multiple components to microwells: 1.) Dilutions of fluorescent dyes in solvent propylene carbonate (PC) are prepared in the source plate and these solutions are then printed into wells of a microwell plate. 2.) PLGA dissolved in PC is added to the microwells and the mixture is sonicated to homogenize. 3.) Surfactant, polyvinyl alcohol (PVA) in water is added to microwells. Step 4.) Generate Particles: Microwells, containing PVA, PLGA, PC and hydrophobic molecules (dyes) and are sonicated to form an emulsion. Step 5–6.) Remove the solvent and wash: 5.) The microwell plate is placed in a vacuum chamber and the PC solvent is evaporated. 6.) Microparticles are washed by centrifugation and buffer exchange with water to remove PVA and residual PC.