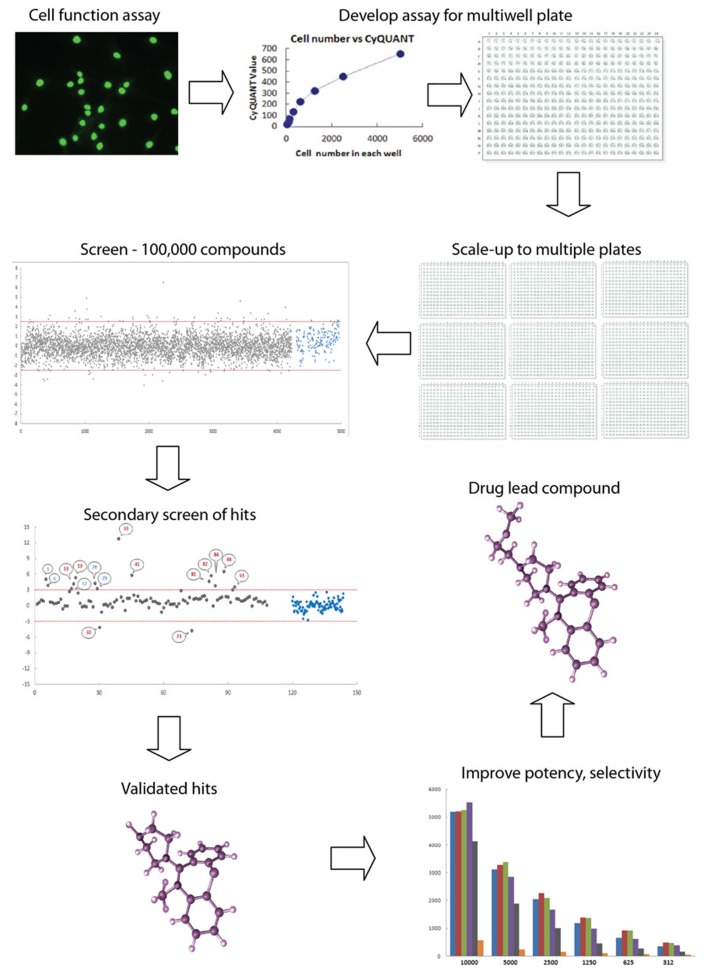

FIGURE 1.

High throughput screening: industrial scale biology. High throughput screening is an automated process for conducting thousands of assays to identify active molecules modulating a biomolecular activity. Assays are performed in multiwell plates with robotics for cell and liquid handling and other aspects such as moving plates from incubator to drug delivery to plate reader. An assay for a cell function of interest must be validated for multiwell plate readers, such as fluorescence, absorbance, or luminescence. Here the assay is a fluorescence assay (Cyquant) for cell number. High levels of quality assurance and quality control are required to reduce the variance of the measurement so that the assay can be reliably scaled to multiple plates. Typically, thousands of compounds are screened for activity, with “hits” being defined as those compounds whose activity on the assay falls outside three standard deviations (red lines) around the mean of the controls on the plate (blue dots). Hits are the gray dots above and below the red lines. Secondary screens are then used to validate the initial hits. These screens may include dose–response curves or assays of related functions of interest, resulting in a selection of “validated hits,” which may comprise fewer than 1% of a typical library of compounds of varied structure. Here the validated hits are the numbered dots above the red line. Validated hits are then further assayed and modified chemically in an iterative process to improve potency, selectivity, pharmacological properties, and toxicological profile to produce a drug lead compound that will go into “preclinicalys” testing in animal models. High throughput screening is applied to large libraries of any potentially bioactive molecules including natural products, small molecule drugs, RNAs, and DNAs.