Table 3.

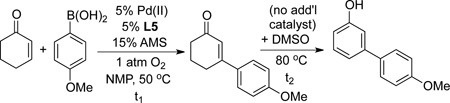

Optimization of Conditions for the Oxidative Heck and one-pot Oxidative Heck/Dehydrogenation Reactions.[a]

| |||||||

|---|---|---|---|---|---|---|---|

| Entry | Oxidative Heck | Oxidative Heck/ Dehydrogenation |

|||||

| Solvent | Conc. [M][b] |

t1 [h] |

Yield [%][c] |

Solvent | t2 [h] |

Yield [%][d] |

|

| 1 | DMSO | 1.3 | 8 | 65 | - | 24 | 64 |

| 2 | DMF | 1.3 | 3 | 95 | - | 24 | 25[e] |

| 3 | NMP | 1.3 | 3 | 90 | - | - | - |

| 4 | Dioxane | 1.3 | 3 | 93 | - | - | - |

| 5 | CH3CN | 1.3 | 3 | 73 | - | - | - |

| 6 | DMF | 2.5 | 3 | 96 | - | - | - |

| 7 | DMF | 5.0 | 3 | 80 | - | - | - |

| 8 | DMF | 2.5 | 3 | - | DMSO | 24 | 54 |

| 9 | NMP | 2.5 | 3 | - | DMSO | 24 | 72 |

| 10 | NMP | 3.1 | 3 | - | DMSO | 24 | 82 |

| 11[f] | NMP | 3.1 | 3 | - | DMSO | 32 | 82 |

| 12[f,g] | NMP | 3.1 | 4 | 95 | DMSO | 32 | 84 |

Reaction conditions: Heck reactions [cyclohexenone (0.75 mmol), boronic acid (0.25 mmol), Pd(II) = [Pd(CH3CN)4](BF4)2, 50 °C, 3–8 h]; Dehydrogenation: temp. increased to 80 °C, 24–32 h (for entries 8–15, 0.2 mL DMSO added).

Conc. of boronic acid.

GC yields.

1H NMR yields.

65% of Heck product recovered.

10% AMS used.

0.5 mmol cyclohexenone.