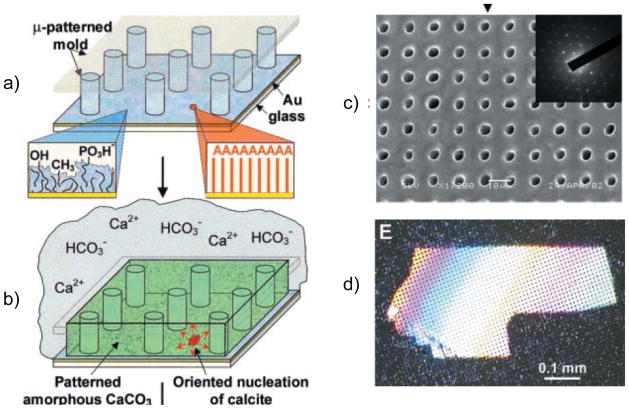

Figure 33.

Aizenberg et al.263 have fabricated micro-patterned single-crystalline calcite using specially designed structural templates with integrated nucleation sites to control the amorphous-to-crystalline transformation. (a) A micropatterned mold prepared by photolithography is treated with SAMs of functionality that suppresses calcite nucleation (such as a disordered phosphate-, methyl- and hydroxy-terminated layer), along with a high supersaturation (1 M Ca2+) to promote ACC. (b) A nanoregion was printed into each template using an AFM tip coated with a SAM of HS(CH2)nA (where A = OH, CO2H), to provide a singular site for calcite nucleation, which then propagated throughout the ACC film, leading to a large single crystal of calcite molded around the array of photolithographically produced posts. (c) SEM of a micromolded and [001] oriented single crystal of calcite. (d) Polarized light micrograph of a large porous single-crystalline patch of calcite. At this time-point, the surrounding ACC film “ruptured” into numerous birefringent spots, thus demonstrating the dimensional limitations that might be encountered in the precursor pathway. The dimensions and chemistry of the template were found to be important for regulating the initial ACC stabilization, as well as its transformation into crystalline calcite. (Reprinted with permission from ref 263. Copyright 2003 American Association for the Advancement of Science.)