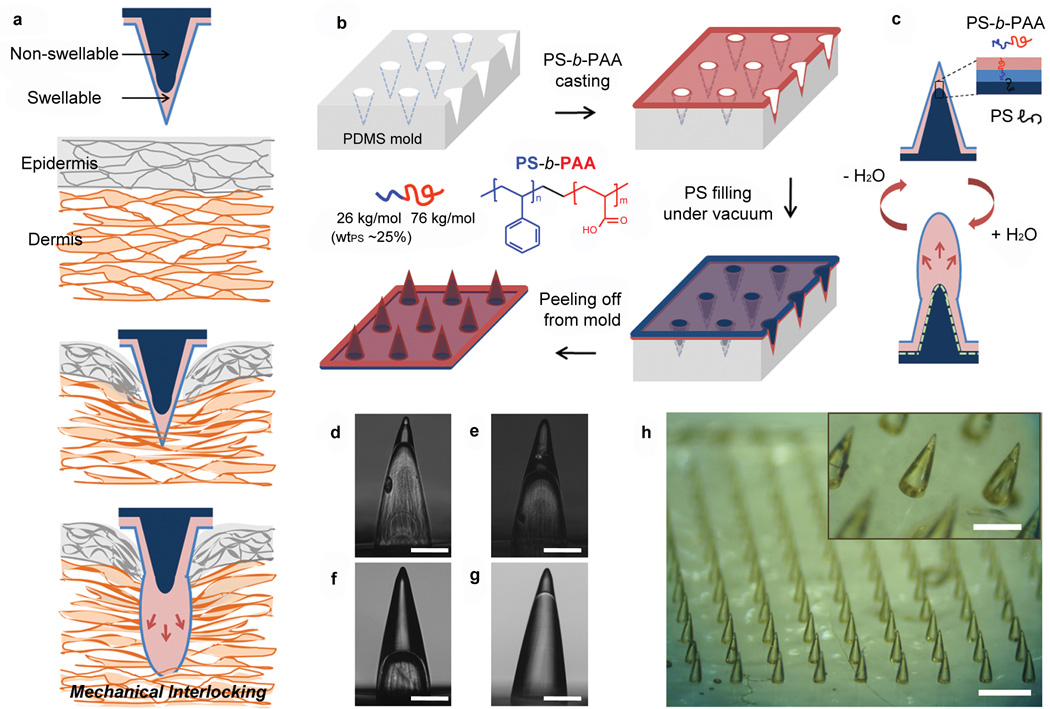

Figure 1. Concept and fabrication of the bio-inspired microneedle (MN) adhesive.

a, Illustration showing mechanical interlocking of a water responsive shape-changeable microneedle following penetration into a tissue. b, Schematic showing the preparation of the double-layered MN array using a PDMS mold and showing the chemical structure of PS-b-PAA with PS weight fraction (wtPS) of 25% used for the swellable tip. c, Cartoon showing the inner structure of double-layered MN and reversible water responsiveness. A thin hydrophobic film comprising the PS block covered the outer surface of the MN, likely due to the presence of the hydrophobic PDMS mold. During fabrication of the of non-swellable PS core, PS chains likely entangle with the PS block at the interface (dashed line) between the swellable tip and PS core providing interfacial adhesion to prevent delamination. d-f, Cross-sectional optical images of hollow MN (without the PS core) with different PS-b-PAA filling fractions including (d) 20%, (e) 40%, and (f) 70% (height of PS-b-PAA layer compared to total MN height). These MNs were prepared by solvent-casting PS-b-PAA dissolved in DMF using different concentrations (d: 10 wt%, e: 18 wt%, and f:25wt%). g, Double-layered MN with a swellable tip (20% height fraction) following filling of the PS core. Scale bar, 200 µm. h, Photograph of the double-layered MN array with density of 10x10/cm2 showing high pattern fidelity. Scale bar is 1mm. The PS-b-PAA tip is clearly distinguishable from the PS core as shown in the inset (Scale bar, 500 µm).