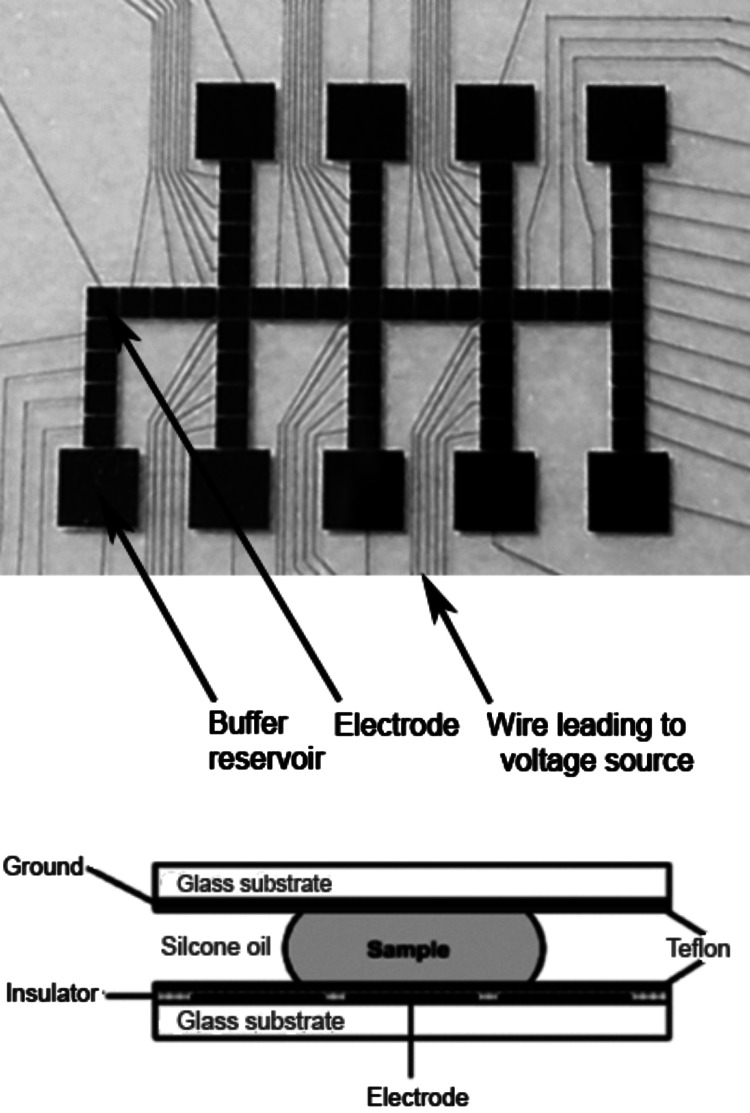

Fig. 7.

Digital microfluidic chip used to perform enzymatic reactions. The top panel is a magnified picture of a digital microfluidic chip of gold electrodes, buffer reservoirs and wires on a glass substrate coated with Teflon. A glass coverslip coated with a transparent and conductive layer coated with a thin layer of Teflon is laid on top of a spacer on this digital microfluidic chip (bottom panel). The gap between the digital microfluidic chip electrode and the glass coverslip is filled with internal silicone oil (this serves to minimize the evaporation of these nanoliter-sized droplets. Samples in aqueous buffer containing Golgi enzymes, UDP-sugars and PAPS are placed on buffer reservoirs through holes in the coverslip and are held in position by applying a voltage to the reservoirs through a connecting wire (Martin et al. 2009). When a voltage is applied to a buffer reservoir or electrode-square the hydrophobicity of the Teflon layer is overcome through electrowetting making the aqueous droplet adhere to the newly hydrophilic surface. Droplets can be split off from the reservoir droplet and moved to the adjacent electrode-square by applying voltages. Once the droplet is transferred to an electrode it can be similarly moved to the adjacent electrode, merged with another droplet or split into two droplets on separate electrode-squares. Thus, enzymes can be added to substrates and reactions can be conducted with both temporal and spatial control.