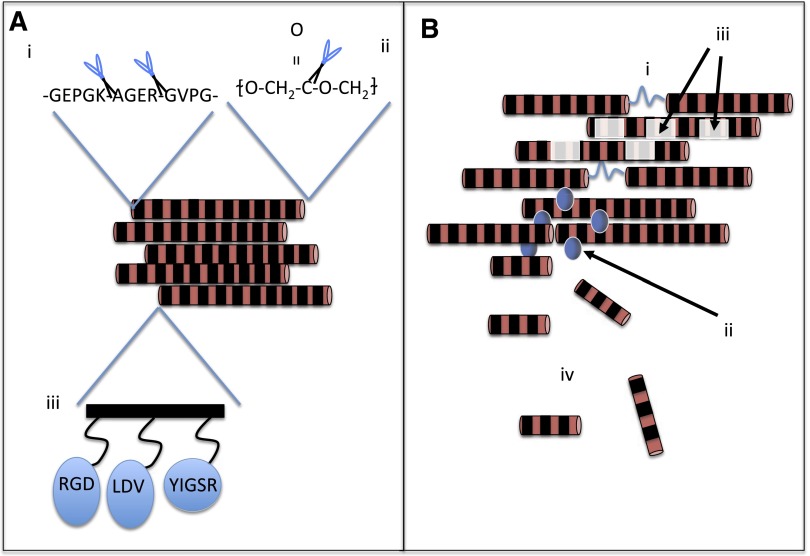

Fig. 7.

Methods to tailor polymeric materials for regenerative medicine applications. Schematic highlights important design parameters for biomaterial scaffold fabrication. (Ai) Proteolytic sequences may be natively inherent (e.g., in natural materials) or engineered into synthetic materials; (Aii) Hydrolytically cleavable sequences may also be a part of the polymer backbone. Synthetic-natural polymer hybrids may allow beneficial aspects of both classes of materials (Xu et al., 2012b); (Aiii) Natural polymers may contain peptidic sequences that promote cell attachment and proliferation through their inherent cell-binding motifs. These amino acid sequences include RGD (e.g., collagen), YIGSR (e.g., laminin), and LDV (e.g., keratin). These sequences may also be grafted into synthetic materials or natural materials that do not contain the sequences inherently (Connelly et al., 2011; Rafat et al., 2012; Sapir et al., 2011). (Bi) Internal bonds that are susceptible to cleavage through internal or external stimuli such as heat, pH, ultrasound, or light (Balmayor et al., 2008; Narayanan et al., 2012; Nelson et al., 2012) allow control over rates of degradation; (Bii) Nano- or microparticles may be also be incorporated into the scaffold (Biondi et al., 2009) and may slowly release their contents (typical for microparticles) or may themselves be released from the material (e.g., nanoparticles). A last important consideration in the material’s degradation is the fashion by which it degrades. These include bulk degradation (Biii) or surface erosion (Biv).