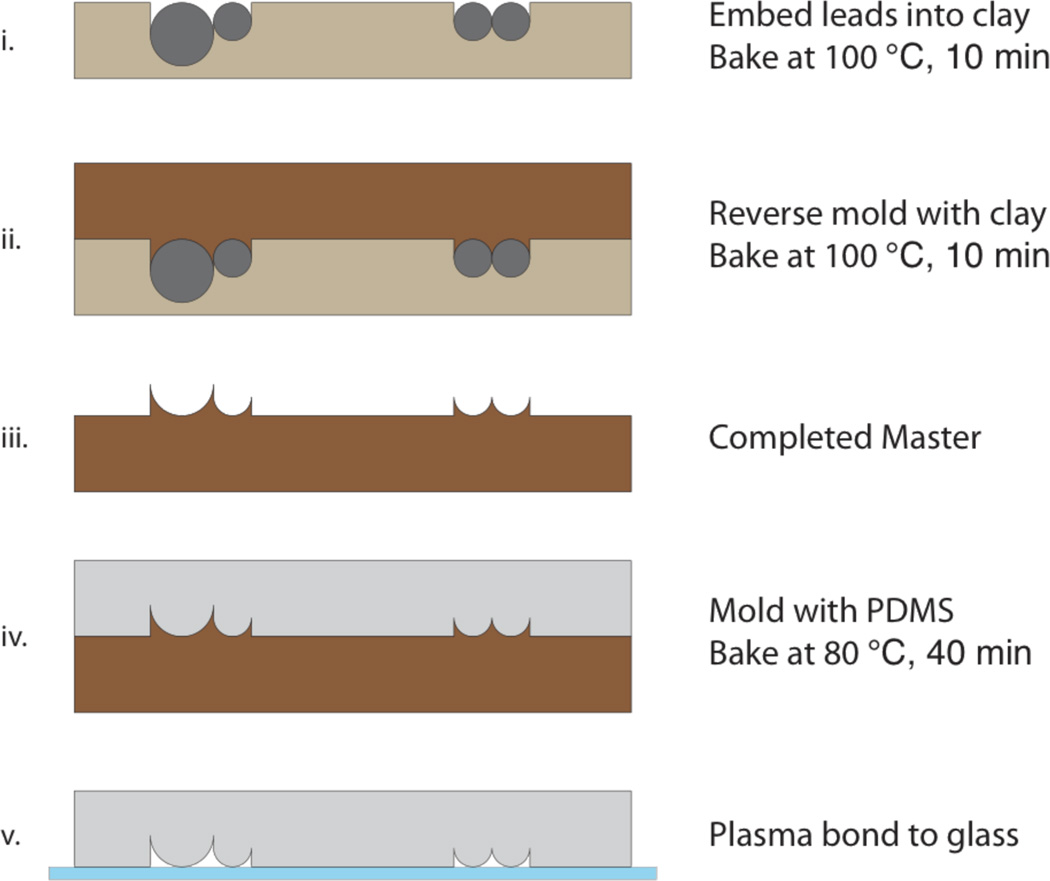

Figure 3.

Device fabrication process. (i) 0.5 mm and 0.3 mm mechanical pencil leads are pressed into molding clay until the tops of the cylinders are flush with the clay surface, and the entire structure is baked. The use of a wider lead results in a larger channel diameter in the completed device. (ii) Additional sculpting clay is pressed into the baked structure. (iii) The reverse-molded clay is baked to form the master mold. (iv) The master is used to cast a PDMS stamp. (v) Access holes are created in the PDMS by using a 3-mm biopsy punch, and the PDMS stamp is attached to a glass coverslip by plasma bonding.