Table 2. Influence of experimental conditions on propylene carbonate yields.*

.

.

| Entry | Catalyst (mg) | TBAB (mmol) | CO2 pressure† (MPa) | Temperature (°C) | Time (h) | Yield‡ (%) | TON§ |

|---|---|---|---|---|---|---|---|

| 1|| | Salen-Co-OAc 81.0 | 1.8 | 0.1 | 25 | 48 | 77.1 | 158 |

| 2 | Co-CMP 100 | 0 | 0.1 | 25 | 48 | 6.7 | 14 |

| 3 | Co-CMP 0 | 1.8 | 0.1 | 25 | 48 | 20.4 | 3¶ |

| 4 | Co-CMP 100 | 1.8 | 0.1 | 25 | 48 | 81.5 | 167 |

| 5 | Al-CMP 95.2 | 1.8 | 0.1 | 25 | 48 | 78.2 | 160 |

| 6 | KI 20.3 | 0 | 0.1 | 25 | 48 | 3.8 | 8# |

| 7 | KI/β-CD 20.3+138 | 0 | 0.1 | 25 | 48 | 3.9 | 8# |

| 8|| | Salen-Co-OAc 81.0 | 1.8 | 3.0 | 100 | 1 | 84.6 | 173 |

| 9 | Co-CMP 0 | 1.8 | 3.0 | 100 | 1 | 31.0 | 4¶ |

| 10 | Co-CMP 100 | 1.8 | 3.0 | 100 | 1 | 98.1 | 201 |

| 11 | Al-CMP 95.2 | 1.8 | 3.0 | 100 | 1 | 91.2 | 187 |

| 12** | Co-CMP 100(O2) | 1.8 | 3.0 | 100 | 1 | 96.0 | 197 |

| 13†† | Co-CMP 100(H2O) | 1.8 | 3.0 | 100 | 1 | 94.1 | 193 |

| 14†† | Al-CMP 95.2(H2O) | 1.8 | 3.0 | 100 | 1 | 72.9 | 149 |

| 15 | KI 20.3 | 0 | 3.0 | 100 | 1 | 3.0 | 6# |

| 16‡‡ | KI/β-CD 20.3+138 | 0 | 3.0 | 100 | 1 | 13.2 | 27# |

All reactions were conducted in the absence of additional solvent unless otherwise noted.

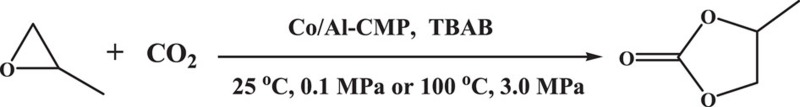

*Reaction conditions: propylene oxide (25 mmol), Co-CMP (100 mg, Co: 0.122 mmol) or Al-CMP (95.2 mg, Al: 0.122 mmol) or Salen-Co-OAc (81.0 mg, Co: 0.122 mmol) or KI (20.3 mg, 0.122 mmol), unless otherwise noted.

†Initial pressure.

‡Yield of the isolated product obtained after column chromatography.

§TON=(moles of product)/(moles of metal in the catalyst), unless otherwise noted.

||Co-CMP was replaced with Salen-Co-OAc in the catalytic reaction. Salen-Co-OAc=[(R, R)-N′N′-bis(5-bromo-3-tert-butyl-salicylidene)-1,2-cyclohexanediaminate] cobalt (III) acetate.

¶TON=(moles of product)/(moles of TBAB in the catalyst).

#TON=(moles of product)/(moles of KI in the catalyst).

**Not excluding the air inside the reaction system.

††0.2 ml of H2O was added to the reaction system.

‡‡β-CD (β-cyclodextrin) (0.122 mmol, 138 mg) was added.