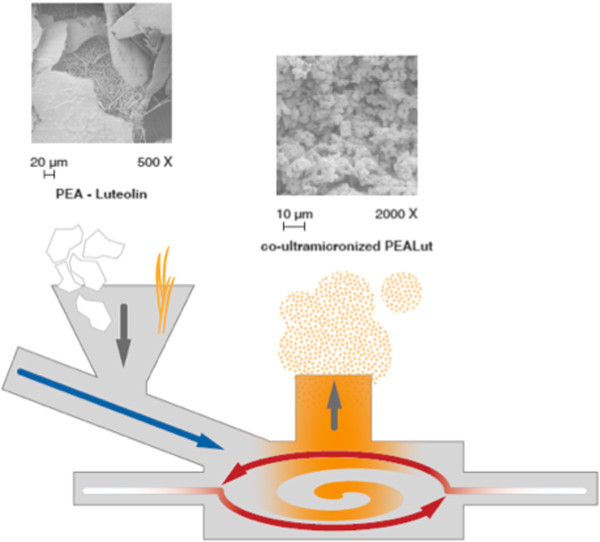

Figure 1.

Schematic representation of the co-ultramicronization process. Once coarse particles of PEA and Lut enter the system through the feed funnel (downwards gray arrow), they are forced to the grinding chamber by compressed air (blue arrow). There, high-speed rotation sustained by grid air (white to red arrows) subjects the coarse mixture to particle-on-particle impact reduction. Centrifugal force holds larger particles in the grinding area, while centripetal force drives preselected-sized fines toward the center for discharge. Depending on its size, the co-ultramicronized particle remains inside the grinding chamber until it has a size that allows the exiting process gas to transport it out, depending on the vortex finder (upwards grey arrow). The scanning electron microscopy views represent the naïve mixture of the two compounds (left-hand side) and the resulting co-ultramicronized composite, ‘co-ultraPEALut’ (right-hand side), respectively. Lut, luteolin; PEA, palmitoylethanolamide.