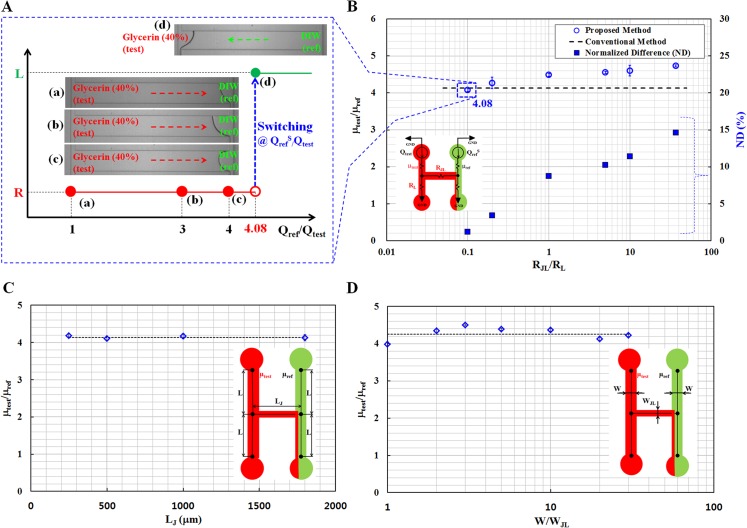

Figure 3.

Performance evaluation results of the proposed method for various design parameters, including the fluidic resistance ratio (RJL/RL), the length of the junction channel (LJ), and the width ratio between the side channel and the junction channel (W/WJL). (A) Microscopic images showing fluidic flow direction in the junction channel depending on flow-rate ratio ((a) Qref/Qtest = 1, (b) Qref/Qtest = 3, (c) Qref/Qtest = 4, and (d) Qref/Qtest = 4.08) for the 40% Glycerin solution as the test fluid and DIW as the reference fluid. The fluidic flow of the Glycerin was reversely moved in the junction channel from right direction (R) to left direction (L), at a specific flow rate ratio of QrefS/Qtest = 4.08). (B) Variation of viscosity ratios (μtest/μref) identified using the proposed method with respect to the fluidic resistance ratios (RJL/RL) between the junction channel and the side channel. The normalized differences (NDs) compare the results obtained by the proposed method and the conventional method. (C) Variations of viscosity ratios identified by the proposed method with respect to various lengths (LJ) of the junction channel ranging from 250 μm to 1800 μm. (D) Variations of viscosity ratios measured by the proposed method with respect to different width ratios (W/WJL) between the side channel and the junction channel.