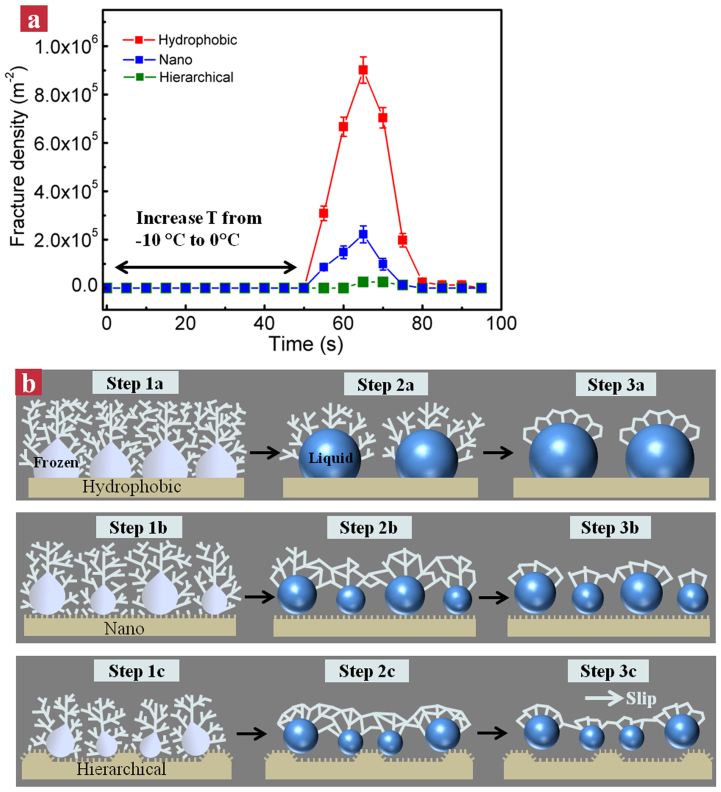

Figure 5. The effects of surface roughness on the frost removal.

(a) The time evolution of fracture densities on three different surfaces. (b) Schematic drawing showing the frost morphology evolution on three different substrates during the defrosting process. Owing to the remarkable large adhesion between the melting frost and the underlying substrate, random fractures emerge in the frost on the flat hydrophobic surface (step 1a–3a). In contrast, the incorporation of nanoscale roughness in the nanograssed or hierarchical surfaces increases the lubrication of liquid between the frost and underlying solid interface (step 1b–3b, 1c–3c), preventing the surfaces from severe fractures. Moreover, the presence of 3-D, inclined microstructures on the hierarchical surface (step 1c–3c) further facilitates the frost movement, promoting the frost removal with an enhanced structural integrity (step 3c).