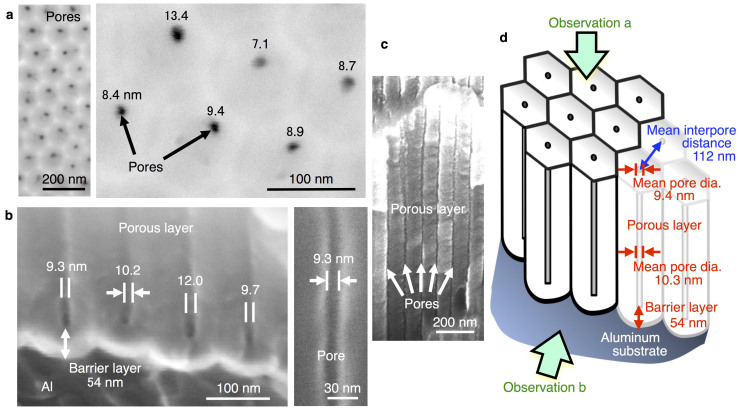

Figure 3. Anodic porous alumina with 10-nm-scale pore arrays fabricated by two-step selenic acid anodizing.

(a), Low- and high-magnification SEM images of the surface of the specimen that was anodized at 48 V for 10 min. The numbers in the figure represent the diameters of each nanopore. The mean pore diameter, averaged from 25 pores, is 9.4 nm. (b), SEM images of the vertical cross-section of the anodized specimen. Porous and barrier layers in the anodic oxide are visible. (c), SEM image of the vertical cross-section of the anodized specimen for 1 h. For panels (a) through (c), no conducting layer was deposited on the surface or cross-section of the anodized specimens to clearly observe the pores. (d), Nanostructural features of the self-ordered anodic porous alumina fabricated by two-step anodizing at 48 V.