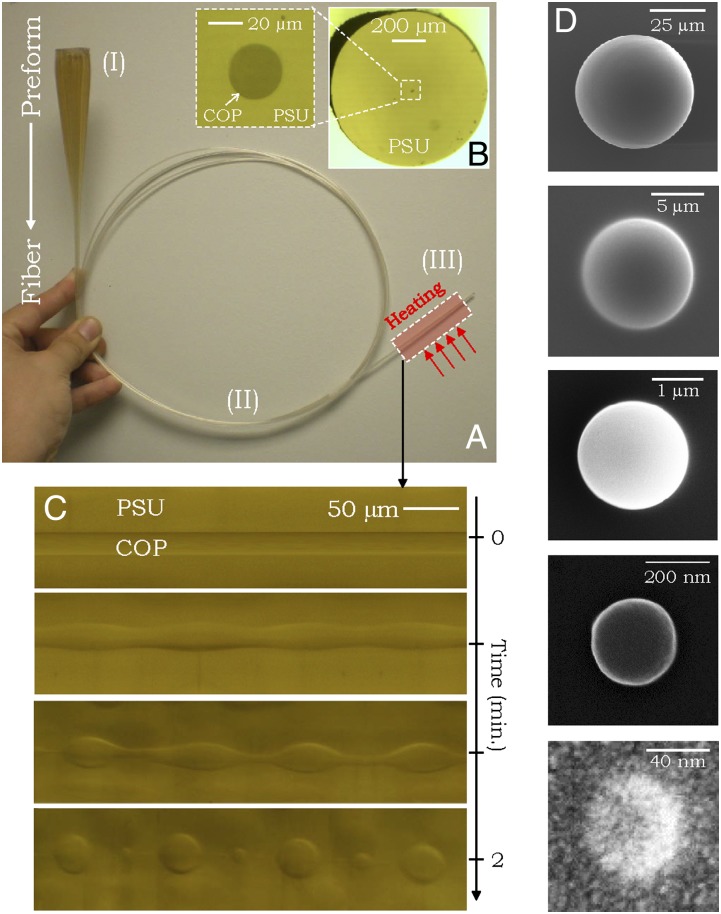

Fig. 1.

In-fiber emulsification as a route to producing spherical polymer particles. (A) Preform-to-fiber approach. A centimeter-scale preform (Upper Left) is drawn into a 1-mm-diameter fiber. The Roman numerals identify the three fabrication stages outlined in the main text. (B) Optical transmission micrograph of the fiber cross-section consisting of a 20-μm-diameter COP core inside a PSU cladding. (C) Side views of a section of a fiber undergoing thermal treatment at 321 °C showing the temporal evolution of the PRI starting from the intact cylindrical COP core until it breaks up into a necklace of particles embedded in the PSU cladding. (D) Size tunability of COP particles, released from the PSU cladding using DMAC, demonstrated in scanning electron micrographs. [Scale bar: D, successively reduced by a factor of 5 (Upper to Lower)]. Particle diameters are ∼53 μm, 10.6 μm, 2.2 μm, 270 nm, and 61 nm. Details of the fabrication process are provided in Supporting Information.