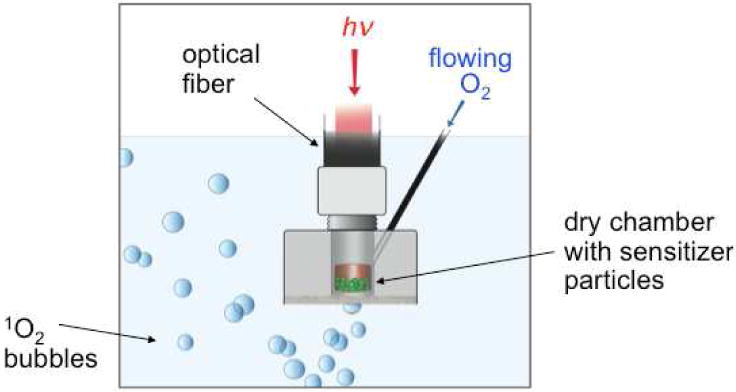

Figure 1.

Cross-section illustration of the 1O2 bubble generation system[7], which was operated in a horizontal or tilted position, consisting of a chamber (5.7 mm diameter, 5.3 mm height) loaded with silicon phthalocyanine glass sensitizer particles (average diameter 150 μm), a hydrophobic microporous membrane (0.05 μm pores and a capillary pressure sufficiently high to exclude water), an O2 gas feed tube, a 669-nm diode laser coupled to a fiber optic where the light entered the top portion of the device at the SMA coupler. The sensitizer particles are shown as a cutaway view of the device chamber. When immersed in water, the device bubbles 1O2, but the sensitizer remains shielded from water. The bubbles penetrate 7 mm into the solution and then reach the outer solution/air interface.