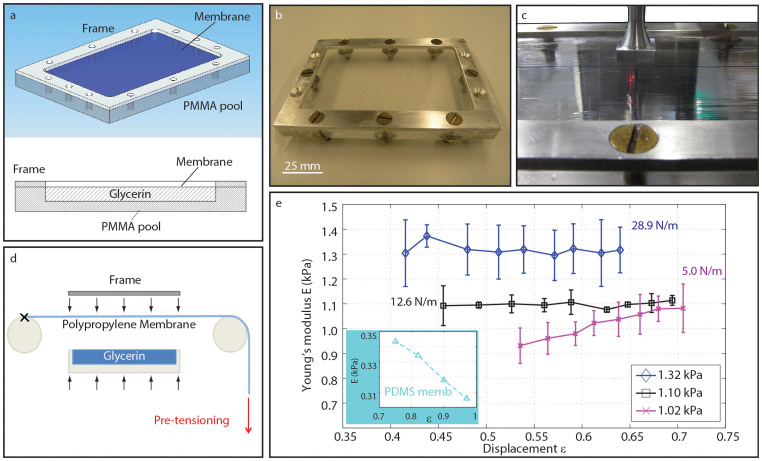

Figure 2. The reflector structure.

(a) Isometric and lateral views. (b) One of the manufactured components (frame) before its use in the reflector device (c) The transparency of polypropylene, glycerin and water allowed laser vibrometer measurements directly during the drop-test experiments. (d) The structure assembly. Pre-tensioning allows the calibration of the final stiffness. (e) Indentation test for three different pre-tensioning values after applying the Dimitriadis model33. The pre-tensioning is measured in N/m as applied tension per unit of width of membrane. The displacement ε is normalized based on the reflector liquid thickness. Young's modulus values: Pretensioning 5 N/m, 1.02 ± 0.07 kPa; 12.6 N/m, 1.10 ± 0.03 kPa; 28.9 N/m, 1.3 ± 0.1 kPa. For smaller Young's modulus, a PDMS membrane was used instead of cellophane. The indentation test showed a strong nonlinearity, and an estimate average Young's modulus of 0.34 kPa. A deformation of 0.7 was already reached for the lowest load of the indentation test.