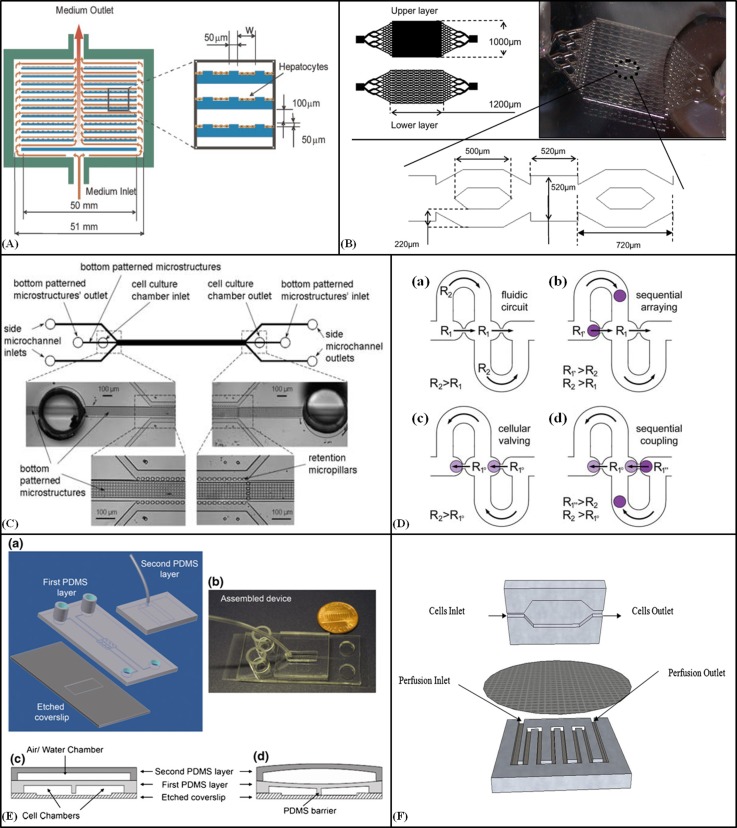

Figure 1.

2D and 3D cell culture. (A) Schematic diagram of the radial-flow bioreactor with microgrooves for 2D culture of Hepatocytes. Reprinted with permission from Park et al., Biotechnol. Bioeng. 99, 455–467 (2008). Copyright 2007 Wiley Periodicals, Inc., John Wiley and Sons. (B) Design of the microfluidic bioreactor for hepatocarcinoma cultivation in 3D cell layers. Reprinted with permission from Baudoin et al., Biochem. Eng. J. 53, 172–181 (2011). Copyright 2011 Elsevier. (C) Schematic diagram of perfusion-based microfluidic device with a series of retention micropillars for 3D culture. Reproduced by permission from Goral et al., Lab Chip 10, 3380–3386 (2010). Copyright 2010 by The Royal Society of Chemistry. (D) The cellular valving principle for cell pairing. (a) A spherical channel with a series of apertures. (b) Cell trapping. (c) Diverting the streamline. (d) Flow reversal used to introduce a second spherical cell type and sequential single cell pairing. Reproduced by permission from Frimat et al., Lab Chip 11, 231–237 (2011). Copyright 2011 by The Royal Society of Chemistry. (E) (a) A schematic of the microfluidic cell co-culture platforms to study cell-cell interactions for 2D and 3D culture. (b) The fabricated device. (c) and (d) Diagrams of the barrier valve working mechanism. Reprinted with permission from Gao et al., Biomed. Microdevices 13(3), 539–548 (2011). Copyright 2011 Springer Science+Business Media. (F) Schematic of the microfluidic 2D cell culture device with a sandwiched PC membrane between culture chamber and perfusion chamber. Reprinted with permission Shah et al., Sens. Actuators, B 156, 1002–1008 (2011). Copyright 2011 Elsevier.