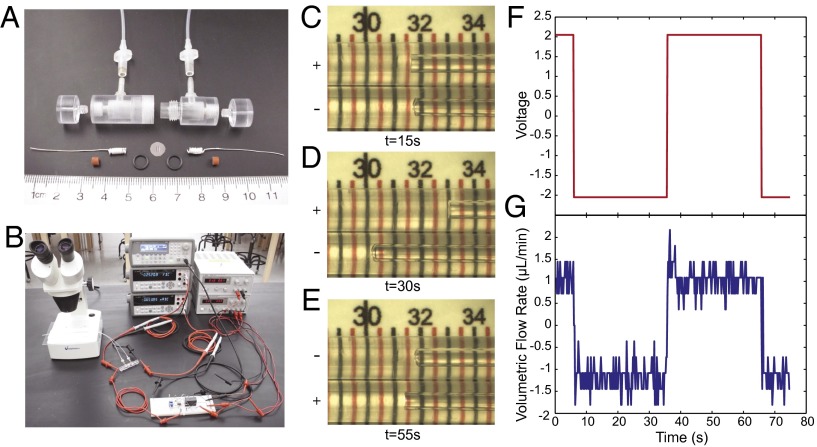

Fig. 4.

Micro-EOP prototype. (A) A prototype pump was developed using a polycarbonate housing that seals a circular pnc-Si membrane chip between two viton O-rings. Silver wire electrodes were wound to produce more surface area and painted with AgCl. Tubing with a 1-μm diameter was attached to the inlet and outlet ports of the device. (B) The pump was driven with a constant-current circuit that switched polarity using a relay (on breadboard). The flow rate was visualized by filming the movement of the solution front in the tubing under a dissection microscope. (C) Screen capture from Movie S1 of the prototype pumping fluid. The inlet and outlet tubes are shown side by side, and the fluid is moving left toward the negative electrode in the bottom tube (current 0.6 mA, voltage 2.05 V changing polarity every 30 s; scale, mm). (D) Screen capture at 30 s. The fluid has moved 1.5 mm in the 15 s between images C and D. (E) An image at 55 s. The polarity has changed at this point and the fluid is flowing left toward the negative electrode in the top tube. (F) Voltage during the time span of Movie S1. (G) Volumetric flow rate as calculated from individual screen captures from Movie S1.