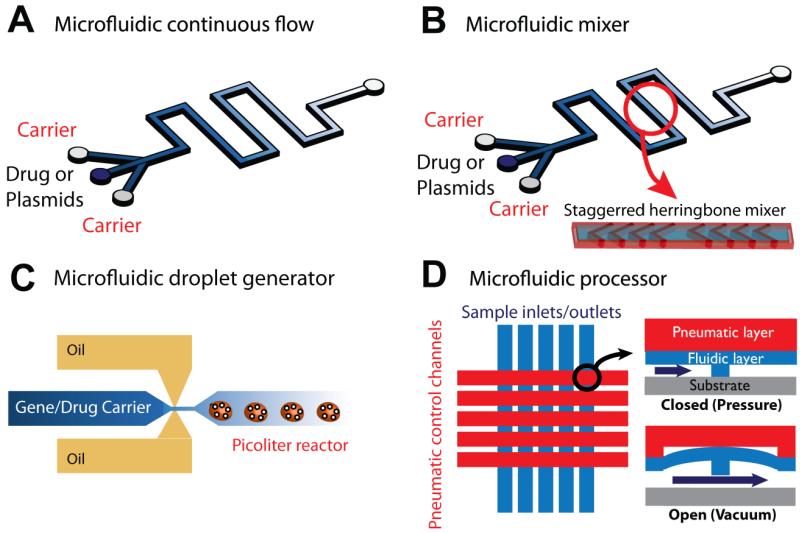

Figure 1.

General design classes of microfluidic platforms for gene/drug carrier production. (A) Simple diffusion based continuous-flow microfluidic fabricator. (B) Passive micro-mixer, or staggered herringbone mixer, with incorporated synthesizer which enables homogenous and rapid mixing between carrier materials and drugs. (C) Microdroplet generator for precise control of carrier size and composition. (D) Programmable pneumatic microfluidic processor for generating large drug carrier libraries [8].