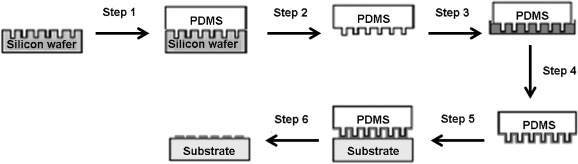

Figure 4.

(Colour online) The μCP process.

Notes: This involves the fabrication of PDMS stamps by depositing a monomeric precursor over a silicon master and cured at 60°C (step 1). The stamp is then peeled from the master (step 2) and immersed into or with a surfactant solution (step 3). Excess surfactant is then removed from the stamp surface (step 4), leaving an ‘ink’. The stamp is then brought into conformal contact with the substrate (step 5), which can include SAM surfaces. The ink is transferred to the substrate where it forms a patterned surface (step 6).