Figure 4.

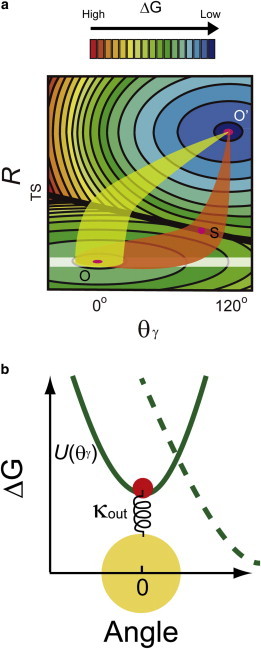

Simulation model of the catalytic reaction rate and viscous drag. (a) Schematic illustration of free-energy surface for pre- or postcatalysis by F1-ATPase drawn for two reaction coordinates, viz. the rotary angle of the γ subunit (θγ) and other degrees of freedom representing the reaction (R). Contours are drawn for evenly spaced energies. The two surfaces intersect on line TS. There are two minima for the surface, located at O and O′ on the pre- and postcatalysis sides, respectively. The saddle point on line TS is denoted as S. When the relaxation time along θγ is shorter than the reaction time of catalysis, the reaction occurs passing through the saddle point on line TS (orange). In contrast, when the relaxation time along θγ is longer, the reaction occurs before θγ has reached the saddle point (light green). (b) Schematic illustration of the Brownian dynamics simulation model. This represents a cross-section view of the 2-D reaction-energy profile cut along the mechanical coordinate. The spring component, κout, intermediates between the γ subunit (red) and the rotary probe (yellow) and was set at 150 pN·nm. U(θγ) represents the inner rotary potential in the reactant side exerted by the stator ring on γ (solid line). The dashed line represents the rotary potential on the product side. The drag friction of γ inside the α3β3 ring, Γγ,, is set at 3 × 10−4 pN·nm s. To see this figure in color, go online.