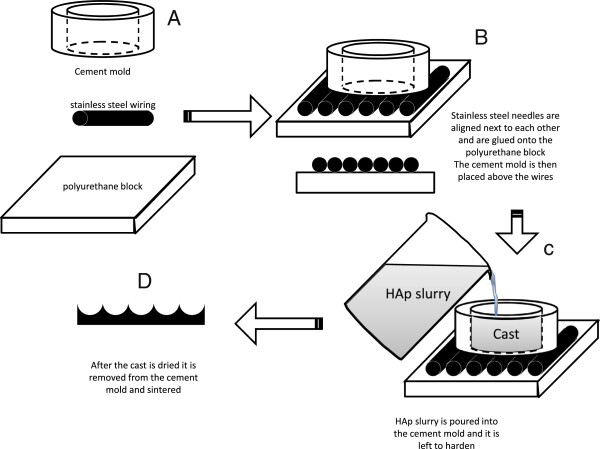

Figure 2.

Diagram showing the steps used to create the molds onto which the HAp was cast. (A) First stainless steel wires of different dimensions were cut 25 mm long and were lined up next to each other in the axial direction on a polyurethane block to form the negative template. (B) These needles were then adhered with epoxy to the PU block to prevent movement. (C) The HAp was then cast into a cement mold (10 mm diameter and 6 mm depth) to form the positive cast. The cast HAp disk was then removed and sintered. (D) The resulting pattern was a series of concave curves.