Table 1.

One-pot, sequential RCM/CM/chemoselective hydrogenation involving type I olefins.

| entry | olefin | yield %a (avg %) |

RCM-CM- chemoselective hydrogenation |

|---|---|---|---|

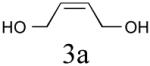

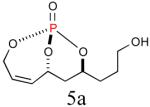

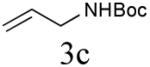

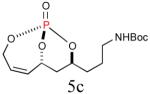

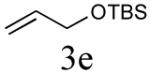

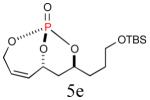

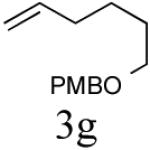

| 1 |

|

64%b (86%) |

|

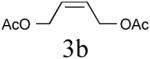

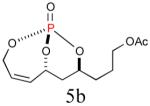

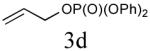

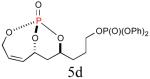

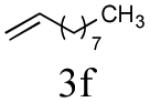

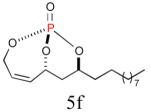

| 2 |

|

56% (82%) |

|

| 3 |

|

59%b (84%) |

|

| 4 |

|

40% (74%) |

|

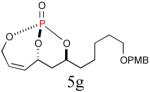

| 5 |

|

52% (80%) |

|

| 6 |

|

65% (87%) |

|

| 7 |

|

43%c (76%) |

|

All reactions were performed using freshly distilled (over CaH2) FDT solvents

1,4-Benzoquinone is not used during RCM event.

Reaction was performed in CH2Cl2 purified by passing through basic Al2O3 and degassed by argon purging without any additives.