Table 2.

One-pot, sequential RCM/CM/chemoselective hydrogenation involving type II olefins

| entry | olefin | yield %a (avg %) |

RCM-CM-chemoselective hydrogenation |

|---|---|---|---|

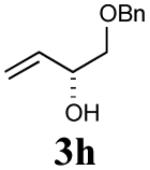

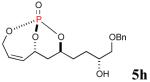

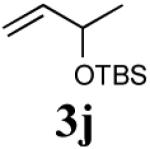

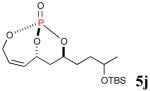

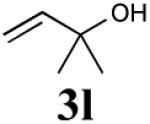

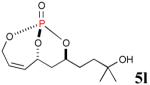

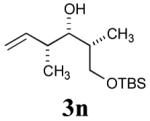

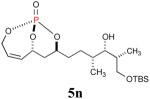

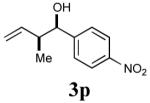

| 1 |

|

41% (75%) |

|

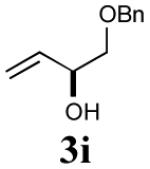

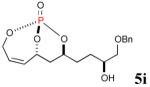

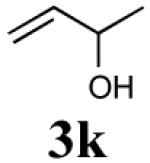

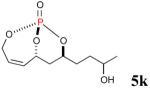

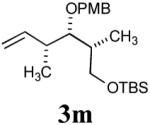

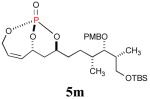

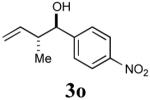

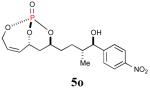

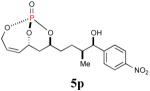

| 2 |

|

35% (71%) |

|

| 3 |

|

69% (89%) |

|

| 4 |

|

48% (78%) |

|

| 5 |

|

72% (90%) |

|

| 6 |

|

30%b (67%) |

|

| 7 |

|

54% (81%) |

|

| 8 |

|

85% (95%) |

|

| 9 |

|

79% (92%) |

|

All reactions were performed using freshly distilled (over CaH2) FDT solvents

Reaction was performed in CH2Cl2, 1,2-DCE purified by passing through basic Al2O3 and degassed by argon purging.