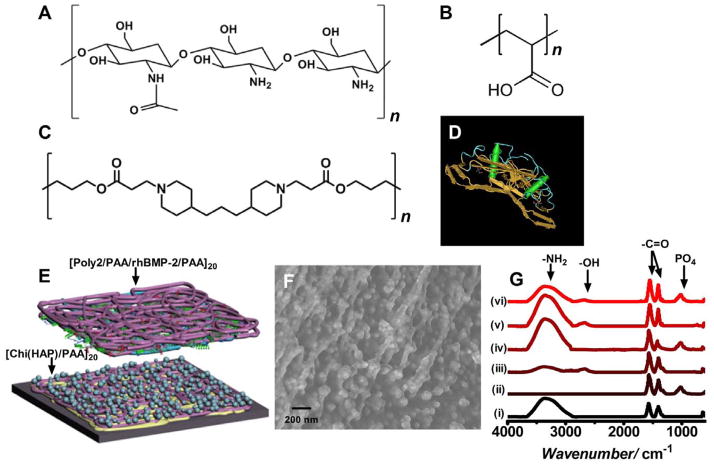

Figure 1.

Design and fabrication of the osteophilic multilayer architecture. Components of the film (A) Chitosan (75%–85% deacetylated chitin), a polycation (B) Poly(acrylic acid) (PAA), (C) A hydrolytically degradable poly(β-amino ester) (Poly2), a polycation and (D) osteoinductive recombinant human bone morphogenetic protein 2 (rhBMP-2) (E) Schematic of the modular electrostatic assembly. Osteoconductive hydroxyapatite is complexed with chitosan and incorporated into nanoscale thick films along with poly(acrylic acid) in a bilayer architecture. A hydrolytically degradable poly(β-amino ester) based multilayer film incorporating osteoinductive rhBMP-2 lays atop the osteoconductive layer. (F) Scanning electron micrograph of a [Chi(HAP)/PAA]20 bilayer film with the complexed hydroxyapatite nanoparticles. HAP particles complexed to chitosan strands are interwoven in the multilayer architecture (G) IR absorbance spectra of the different components of the osteoconductive layer (i) chitosan (ii) hydroxyapatite (iii) poly(acrylic acid) (iv) [Chitosan/HAP]1 (v) [Chitosan/PAA]20 and (vi) [Chi(HAP)/PAA]20.