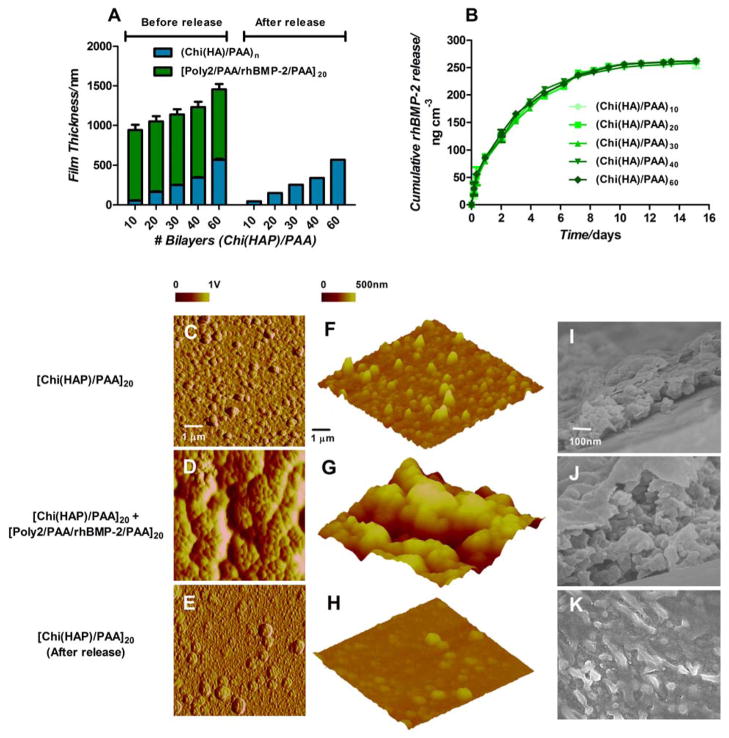

Figure 2.

Characteristics of multilayer properties during assembly and degradation. (A) Multilayer film thickness increases linearly with incremental osteoconductive [Chi(HAP)/PAA] layers. Contributions of film thickness from the growth factor eluting layers (green) and hydroxyapatite containing layers (blue) are provided. (B) rhBMP-2 released from the films over 2 weeks. Surface and bulk morphologies of [Chi(HAP)/PAA]20 + [Poly2/PAA/rhBMP-2/PAA]20 multilayer films (C, F) HAP particles are distributed uniformly in the osteoconductive [Chi(HAP)/PAA]20 multilayer surface, and the features are made rougher in (D, G) by the conformal coating of the [Poly2/PAA/rhBMP-2/PAA]20 layers. (E, H, K) Once the growth factor is released by the degradation of the poly(β-amino ester) layers, there is an observable reduction in surface roughness. (F, G, H) Surface height profiles confirm that HAP particles are uniformly distributed with a lack of sequestration in a particular area. (I, J) Corresponding cross sectional scanning electron microscopy images confirm the presence of particles throughout the bulk of the film (I, J, K are at the same scale). C–H are atomic force microscopy images, where C–E are phase contrast images, F–H are height images. I–K are scanning electron microscopy images.