Table 1.

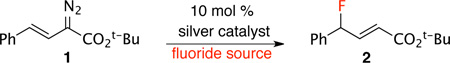

Vinylogous Fluorination Optimizationa

| |||

|---|---|---|---|

| entry | catalyst | fluoride | yield (%)b |

| 1 | AgOAc | TMAF | <5 |

| 2 | AgOAc | TBAFc | <5 |

| 3 | AgOAc | TBABF | <5 |

| 4 | AgOAc | KHF2d | <5 |

| 5 | AgOAc | Fluolead™ | <5 |

| 6 | AgOAc | TASF | <5 |

| 7 | AgOAc | Deoxo-Fluor | 44 |

| 8 | AgOAc | DAST | 55 |

| 9 | AgOAc | Et3N-3HF | 90 |

| 10 | AgSbF6 | Et3N-3HF | 88 |

| 11 | AgOTf | Et3N-3HF | 90 |

Vinyldiazoacetate (0.4 mmol, 1.0 equiv), silver catalyst (10 mol %), fluoride source (2.0 mmol, 5.0 equiv), under refluxing in dichloromethane.

Isolated yield, <5 refers to no observation of product 2 from 1H NMR analysis prior to chromatography.

1.0 M in THF.

Dry DMF as solvent at 90 °C.