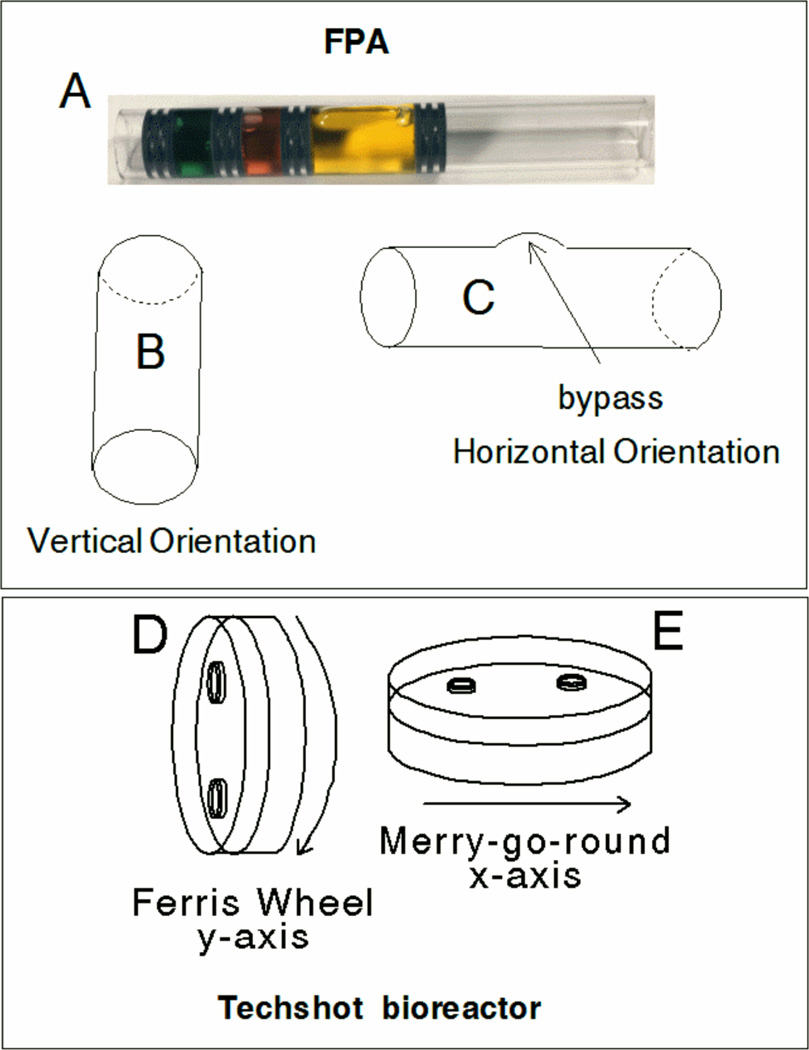

Figure 3. Fluid Processing Apparatus and Techshot bioreactor orientations.

FPA diagram (A) shows a loaded example in which 1×107 cells were placed in three ml of medium in chamber 1 (yellow) separated by two rubber septa. The FPA is engineered with a bypass so that when the second septum from the right crosses the bypass during motion from left to right the medium in the second chamber (red, 1.5 ml) will mix with the material in chamber 1 and the first two septa from the right will compress together. The next two septa also compress with additional movement to mix the contents of chamber 3 (green, 1.5 ml) with the contents previously mixed; showing vertical (B) or horizontal (C) orientation. The Techshot bioreactor was incubated in a vertical (Ferris wheel) or (E) horizontal (merry-go-round) configurations and rotated at 1 RPM.