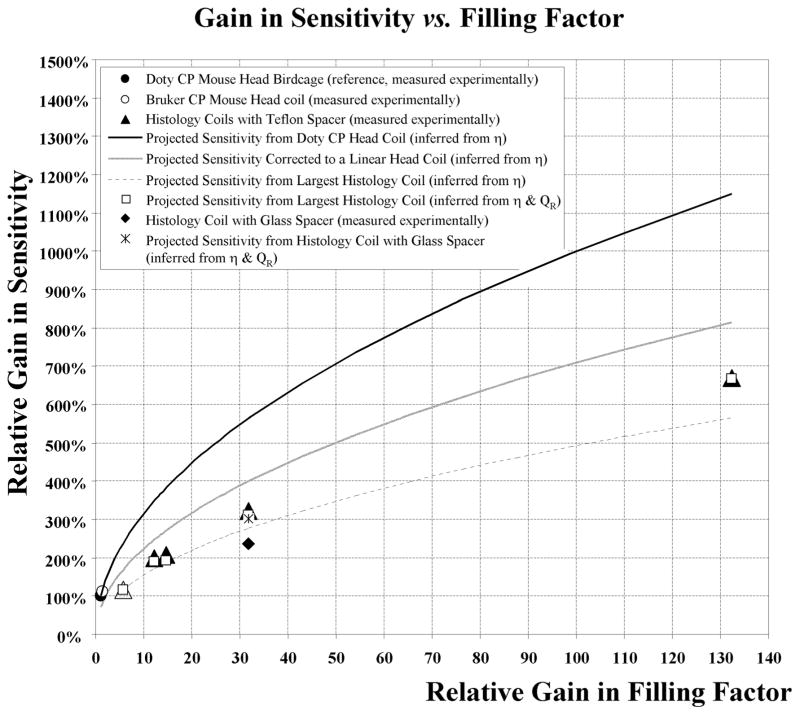

FIG. 4.

Summary of the sensitivity of all the coils utilized in this study (Commercial Birdcage coils: open and filled circles, Histology coils: open and filled triangles and diamond) as a ratio of the effective SNR to that of a commercial mouse head RF coil used as our reference (filled circle) using the same sample for all coils. The solid black line depicts the projected increase in sensitivity of the reference CP birdcage coil that would result from the gain in filling factor achievable by the various RF histology coil using equation [1] (here Q is unaccounted for). The grey line is the sensitivity scaled down by 1.4 in the case of a linear birdcage coil structure. The difference between the grey line and triangles illustrates the systematic underperformance of the histology coils by a factor up to 1.4-fold compared with the linear birdcage coil structure. Similarly, the dashed line plot was inferred using the measured sensitivity of the largest histology coil (open triangle) as the baseline. All lines were calculated with the assumption that the effect of the Q factor remained unchanged. The dashed line curve also showed a deviation from the measured values (triangles) but this time the flat histology coil structures exhibited improved performance as the measured Q increased as their size decreased. Using Eq. [1], this difference was accounted for by incorporating the relative experimentally measured QR, resulting in values (open squares) in good agreement with measured SNR (open and filled triangles). The substitution of the Teflon spacer by a three-layer glass insert while maintaining the identical filling factor resulted in a 26% measured loss of relative sensitivity (filled diamond). However, the corresponding Q factor relative to the Teflon spacer exhibited only a 6% decrease that should lead to only a 3% drop (star) according to Eq. [1] leaving 23% loss unaccounted for. In contrast, the replacement of the Teflon with an air gap insert led to a negligible change (data not shown).