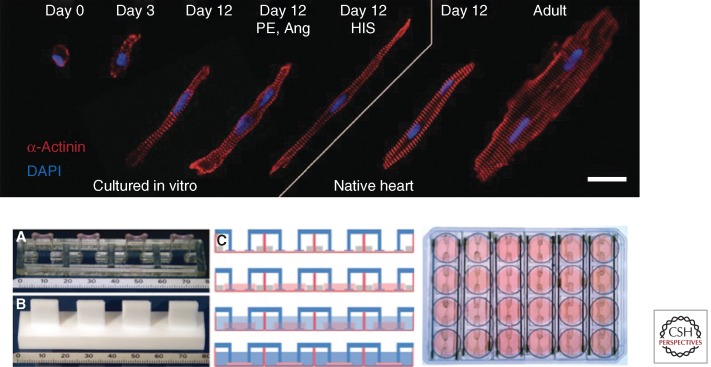

Figure 3.

In vitro testing platforms. (Top) Engineered cardiac tissues can reach the level of advanced morphologic differentiation and maturation typical of their age-matched in vivo counterparts. Hypertrophic cardiomyocyte growth in hydrogel with the application of mechanical stretch is compared to native heart. Cardiomyocytes from engineered tissues at culture days 0, 3, and 12 from three experimental groups: (1) untreated, (2) treated with phenylephrine (PE, 20 µmol/L), angiotensin II (Ang, 100 nmol/L), and (3) treated with hypertrophy-inducing serum (HIS) are compared to cardiomyocytes from rat myocardium. Red, α-actinin; blue, DAPI-labeled nuclei. Scale bar, 20 µm. The image is an assembly of individual immunostains of representative cells from each group. (From Tiburcy et al. 2011; reproduced, with permission, from the author.) (Bottom) Experimental setup for casting and cultivation of cardiac tissue. (A) Silicone post rack with four tissues, turned upside down, scale in mm. (B) Teflon spacer to generate agarose molds, turned upside down, scale in mm. (C) Generation of cardiac tissues. First lane, Casting molds are generated in 24-well plates using agarose and Teflon spacers. Silicone racks are placed on the dish, pairs of posts reach into each mold. Second lane, Cell suspension in Matrigel, fibrinogen, and thrombin is pipetted into the molds. Third lane, Two hours later, the hydrogel is polymerized, with silicone posts embedded in hydrogel at both ends. The constructs are removed from the molds and transferred to 24-well plates. Fourth lane, The constructs are maintained in culture for 15 to 30 days. (From Hansen et al. 2010; reproduced, with permission, from the author.)