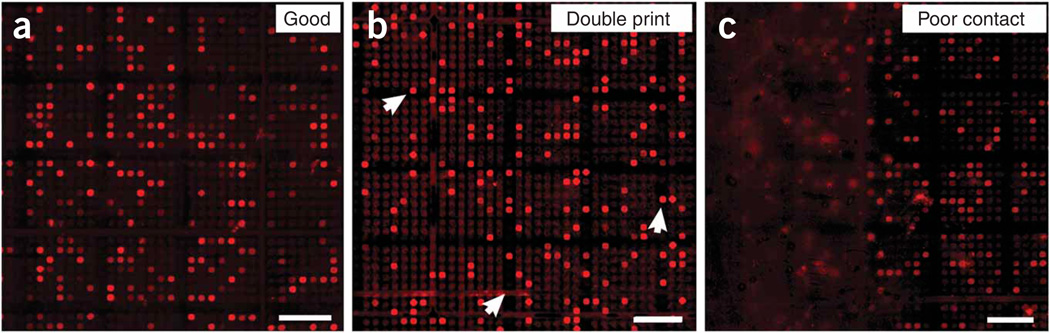

Figure 6.

Examples of potential variations in the quality of the microarrays produced by microengraving. (a) Micrograph of a typical, high-quality microarray resulting from successful application of the technique. The position of each positive spot is unique, and each spot has a well-defined shape. (b) Micrograph from a microarray obtained from a print in which the array of microwells moved while sealing to or separating from the glass slide. Double printing will occur if the array is lifted and repositioned, dragged over the surface of the slide, or if uneven pressure is applied to PDMS; the latter two may also result in smeared features. Arrowheads highlight some features that are out of register. (c) Micrograph of a microarray resulting from poor contact between the glass slide and the array of microwells. Secreted antibodies diffused over the surface of the glass, and individual, localized features are not evident. The contrast and brightness of each image was optimized automatically by GenePix Pro. Note that the format of the arrays in these images differs slightly from the scheme shown in Figure 2; the blocks in these arrays comprised 7 × 7 microwells. Scale bars, 500 µm.