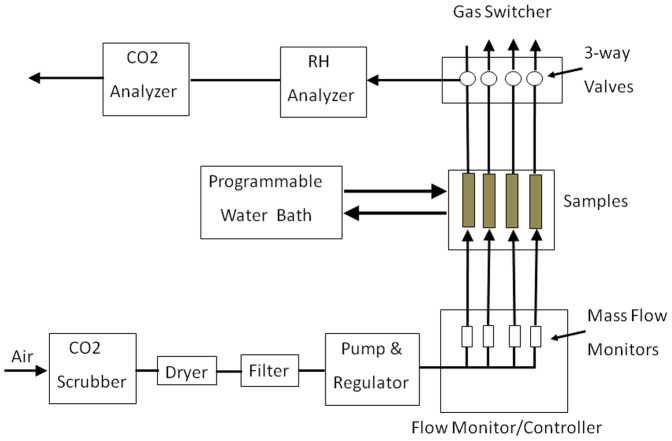

Figure 1. A block diagram of the multi-channel gas exchanger system (www.qubitsystems.com) that was used to assess differential respiration in the microcosms.

Room air was pumped, while regulated by a gas flow controller (pump and regulator), through soda lime to remove CO2 (scrubber; A382), a drier (Dri-Rite; Chicago, USA), and an air filter. Flow (shown as black arrows) was regulated in each sample (shown as grey cylinders) at 50 mL min−1 with a flow monitor (G249 controller). Prepared soil samples were placed in sterilized 218.5 mL plastic tubes with sterile glass wool packed at both ends. Temperature was maintained with a programmable bath filled with ethylene glycol, and both temperature and humidity were monitored using sensors and a monitor (S161), as well as thermister probes (S132; not shown) fitted into ports and sealed into the container tops. Soil respiration at 1 ppm resolution was assessed using an infared CO2 analyzer (S151) by sampling gas with the gas sampled sequentially by three-way valves associated with a switcher (G243). Differential respiration was calculated using software (C950) that automatically subtracted the mean CO2 production in a particular microcosm from the autoclaved sand control (sample 1).