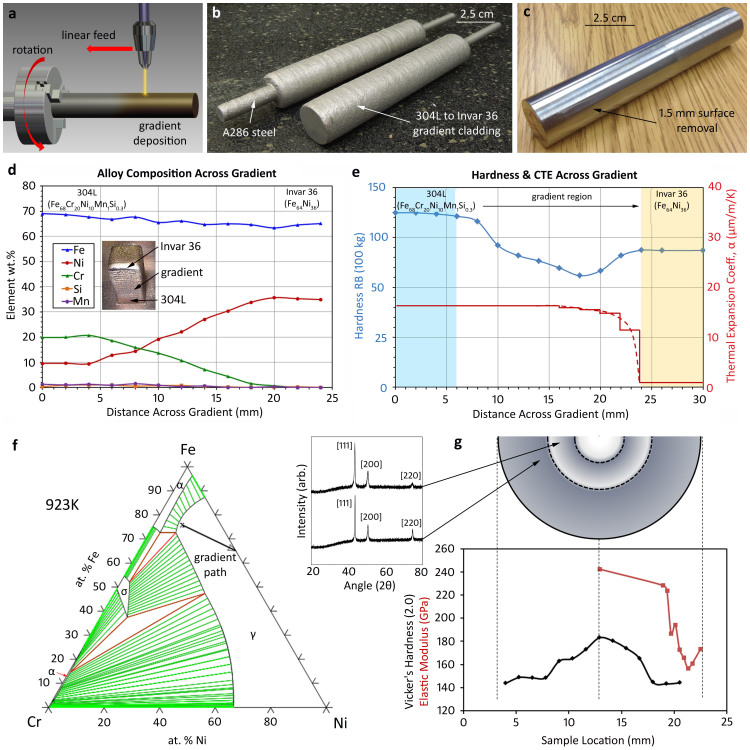

Figure 2. Developing a radially graded alloy.

– (a) Schematic of the rotational deposition process used to develop alloys with gradient compositions in a radial direction. (b) Image of two radially graded alloys where a 304 L to Invar 36 gradient was applied to a rotating A286 stainless steel rod. (c) After removal of 1.5 mm of surface layer, a fully dense gradient rod is obtained. (d) A plot of composition vs. distance for a 304 L to Invar 36 gradient alloy post. (e) A plot of Rockwell B hardness and coefficient of thermal expansion vs. distance for the gradient alloy from (d). Solid red lines connect experimental measurements and dashed lines are theoretical estimates. (f) A calculated phase diagram at 923 K showing a “gradient path” from 304 L to Invar 36. (g) Nanoindentation on the gradient rod shown in (b–c) showing Vickers hardness and modulus (utilizing the same axis). X-ray scans are shown in the insets for two locations near the gradient.