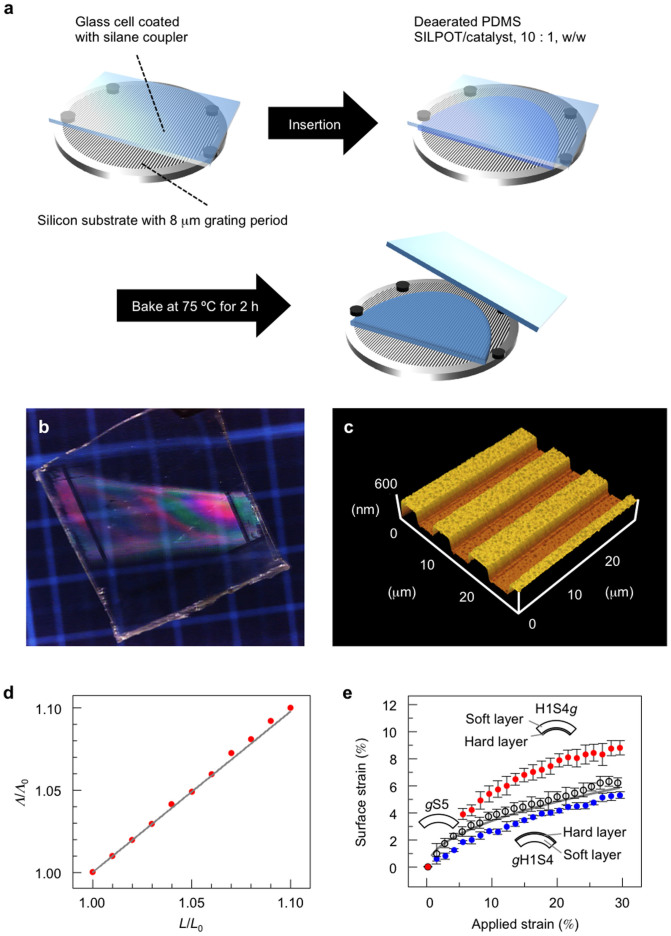

Figure 4. Surface labelling based on surface-relief gratings in PDMS films.

(a), Fabrication principle of PDMS-based surface-labelled gratings. For single-layer films, the glass cell is prepared using 500 μm spacers between a glass substrate and a silicon substrate, for a surface-relief grating with 8 μm periodicity. A mixture of Sylpot and catalyst (10:1 (w/w) for the soft film and 5:1 (w/w) for the hard film) was injected into the cell by capillary force and baked for 2 h at 75°C. After removing the film from the substrates, a free-standing PDMS film was obtained. The detailed procedure is shown in Supplementary Fig. S6 online. (b), Photograph of a 500-μm thick surface-labelled PDMS film. (c), An AFM image of a surface-relief grating on a PDMS film. (d), Simultaneous measurement of the strains generated under external mechanical stress using a thermomechanical analyzer (L/L0). The surface-labelled grating method (L/L0) shows that the strains match perfectly at least up to 10.0%. (e), Strains at the outer tensile surfaces of mechanically bent single-layer and bilayer (with hard and soft layers) PDMS films as a function of the ratio of pressed distance to the initial film length (applied strain). The grey line is the calculated surface strain by equation (1)9. Mean values of n = 5 and 3 films are plotted for single-layer and bilayer films, respectively. Error bars represent standard deviation.