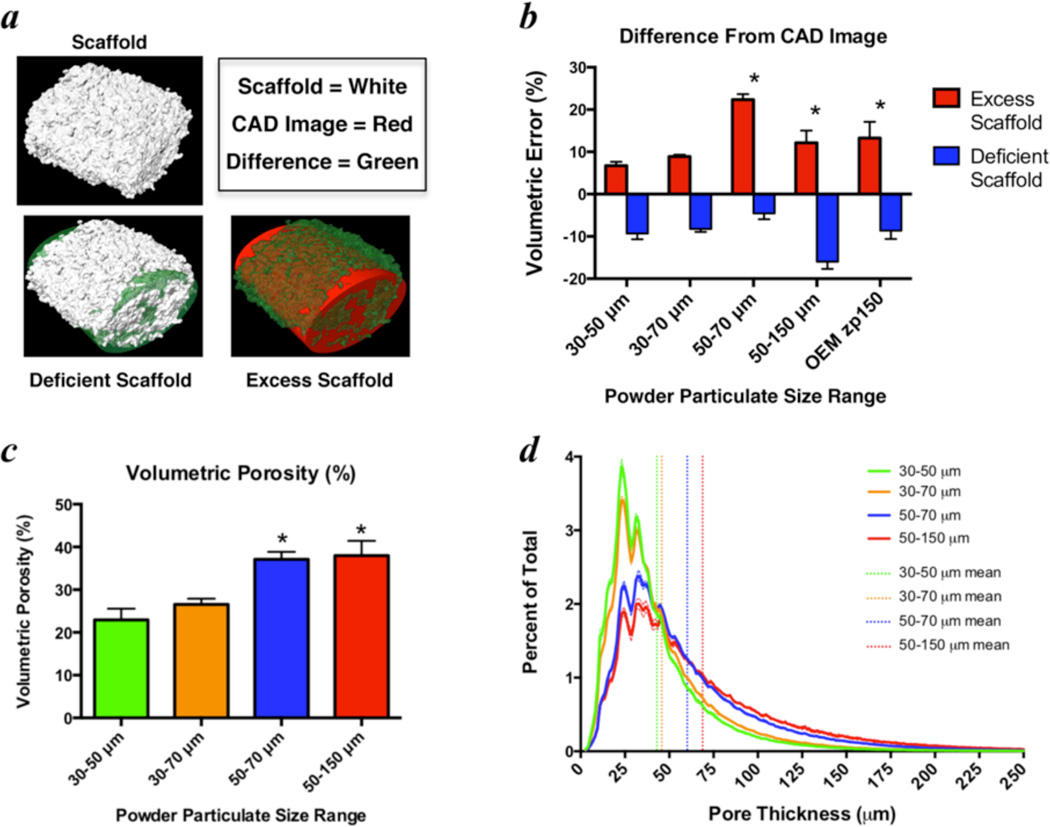

Figure 2. Optimization of powder particle size for 3D printing accuracy of murine-sized femoral scaffolds.

a) 3D image renderings from micro-CT scans of 3 mm murine femoral scaffolds were used to measure the printing accuracy relative to the ideal computer-aided design (CAD) image, which was utilized to guide the printing process. b) Volumetric differences were quantified as the sum of deficient scaffold (where scaffold material should exist, but does not) and excess scaffold (where scaffold material exists, but should not) and were normalized to the total scaffold volume. Volumetric porosity (c) and pore size (d), estimated from the same micro-CT images, were primarily dictated by the lower limit of the powder particle size. * indicates significant differences (p < 0.05) from 30–50 µm powder by ANOVA with Dunnett’s correction for multiple comparisons. Absolute volumetric error was used for statistical comparison in (b). Bars represent means and error bars are standard deviation. n=4–5/group.