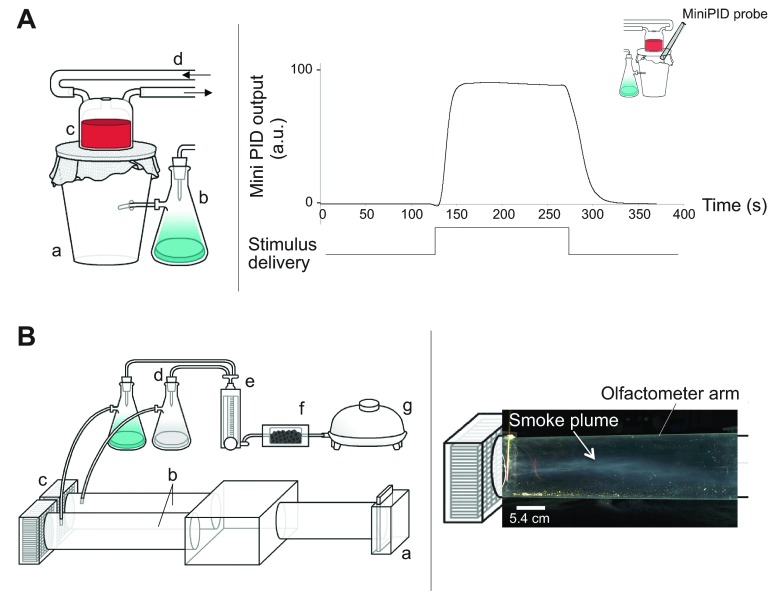

Fig. 1.

Illustration of methods for olfactory training and testing. (A) Left: artificial feeder used in the appetitive conditioning procedure. It allows the pairing of the presentation of an odorant [conditioned stimulus (CS)] with a heated [unconditioned stimulus (US)] blood reward (associative conditioning). a, Plastic insect container; b, glass bottle containing the CS, connected to an air pump via silicone tubing; c, glass artificial feeder; d, silicone tubing conducting warm water (37°C) from a water bath to the artificial feeder. Right: miniaturized photoionization detector (miniPID) characterisation of the stimulus delivery, using a low molecular weight volatile (ethanol) as a tracer. The probe of the miniPID was positioned at the junction between the central box and the olfactometer arms. (B) Left: olfactometer designed for the analysis of the olfactory orientation of mosquitoes. a, Releasing chamber; b, decision arms of the olfactometer; c, computer fans, filters and screens; d, glass bottles containing either the CS or the solvent-control solution; e, flowmeter equipped with a valve needle; f, charcoal filter; g, air pump. Right: visualisation of the stimulus plume structure using a smoke plume. The series of flow straighteners and mesh screens in the olfactometer provided a unidirectional airflow that rapidly created a filamentous plume when the odour left the nozzle from the odour line. For all experiments, the air speed of the stimulus line represented 25% of the air velocity generated by the olfactometer fans.