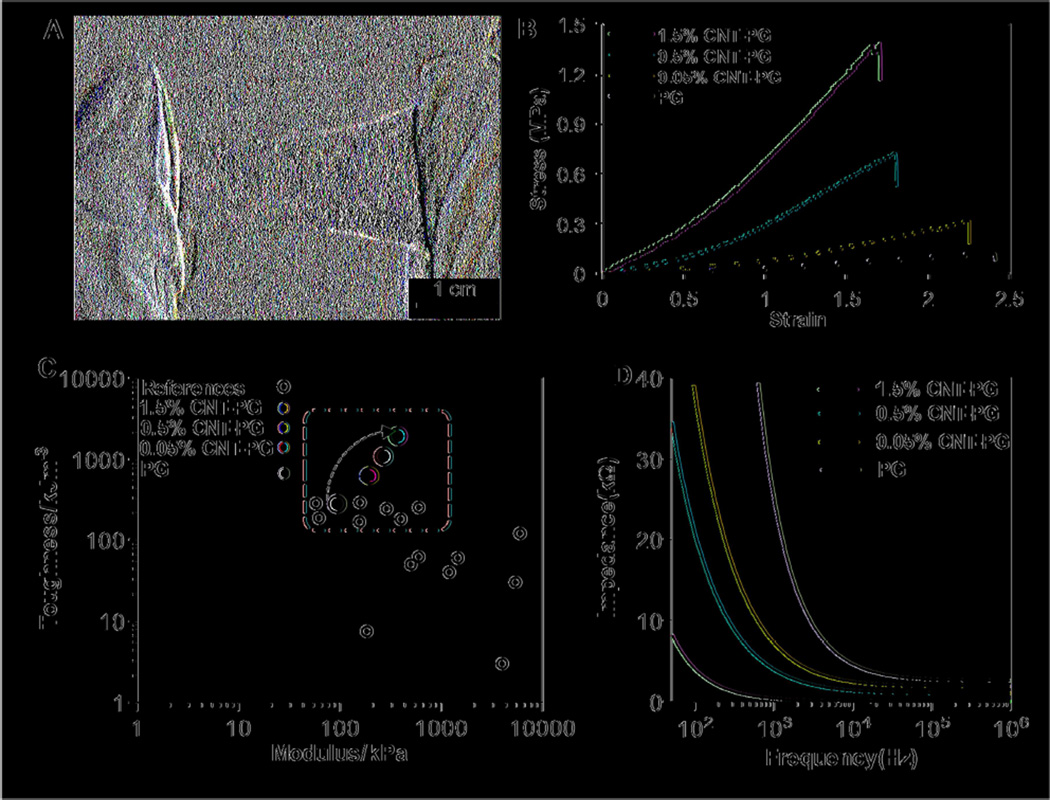

Figure 2.

Physical and electrical characteristics of CNT-PG scaffolds. A) A representative optical image of tough 1.5% CNT-PG scaffold demonstrating easy manipulation of the scaffold. B) Representative stress-strain curves of crosslinked scaffolds after 3 days of soaking in DPBS demonstrating significant improvement in mechanical properties of the scaffolds by increasing the CNT concentration. C) Comparison of the elastic moduli and toughness for previously reported compliant fibrous scaffolds (open circle) [18, 23, 40–46] and the proposed CNT-PG scaffolds consisting of 0% (purple circle), 0.05% (blue circle), 0.5% (red circle) and 1.5% (light green circle for aligned and dark green circle for random nanofibrous scaffolds) CNTs in hydrated state; The dashed window demonstrates the region including the previously developed and the presented CNT-PG tough fibrous scaffolds. As indicated by the arrow, the toughness of the PG scaffolds significantly enhanced through increasing the CNTs concentration. D) The overall impedance of 60µm thick scaffolds as a function of CNTs concentration showing a drastic decrease in impedance through CNTs content.