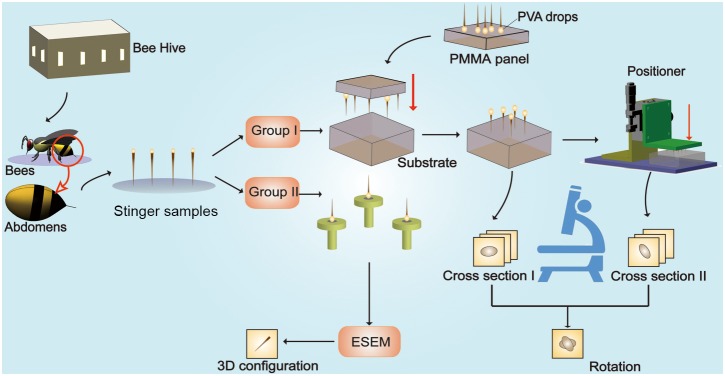

Figure 2. Preparation of the stinger samples and the experiments.

The stingers of worker bees were collected and separated into two groups. (1) The first group of stingers were placed onto the polymethyl methacrylate panel using drops of 15% polyvinyl alcohol (0.1 µL), and they were then placed vertically on the substrates (agar, silica gel, soft rubber and paraffin wax), before pushing the stingers into the substrates at a velocity of 6 mm mm/s using the positioner. The positioner, also called the precision position platform, is a machine that is able to push tiny appendages accurately into the substrates following the planned kinematics, for instance the preset average velocity, the total displacement even the acceleration. (2) The microstructures of the second group of stingers were observed using an environmental scanning electron microscope.