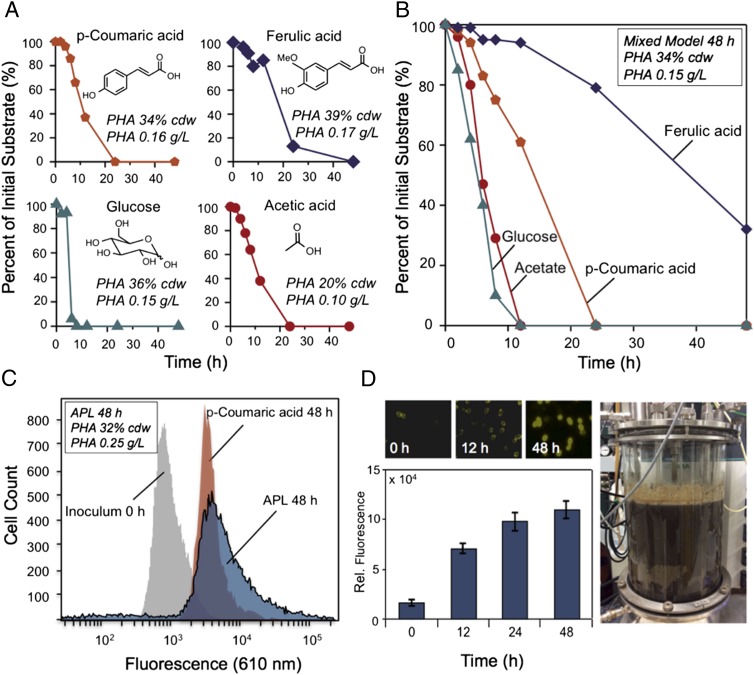

Fig. 2.

Biological conversion of lignin-derived aromatic molecules and carbohydrate-derived products in APL to mcl-PHAs in P. putida. (A) Conversion and mcl-PHA production from representative model compounds present in APL, each at 2 g/L. (B) Conversion and mcl-PHA production of a mixture of four representative model compounds from APL, each loaded at 0.5 g/L. (C) Flow cytometry of Nile Red-stained cells for mcl-PHA accumulation. Cell counts are plotted as a function of fluorescence intensity in the initial inoculum (t = 0) and cultures at t = 48 h for a model substrate, p-coumaric acid, and APL grown in 250-mL shake flasks, with the corresponding total mcl-PHA production from APL shown in Inset. (D) Fluorescence imaging of cells at 0, 12, and 48 h stained with Nile Red demonstrates mcl-PHA production from APL (Upper). Fluorescence quantitation of P. putida cells from the APL conversion as a function of time adjusted to an equivalent cell density (Lower). Biological APL conversion by P. putida in a 14-L fermenter (Right).