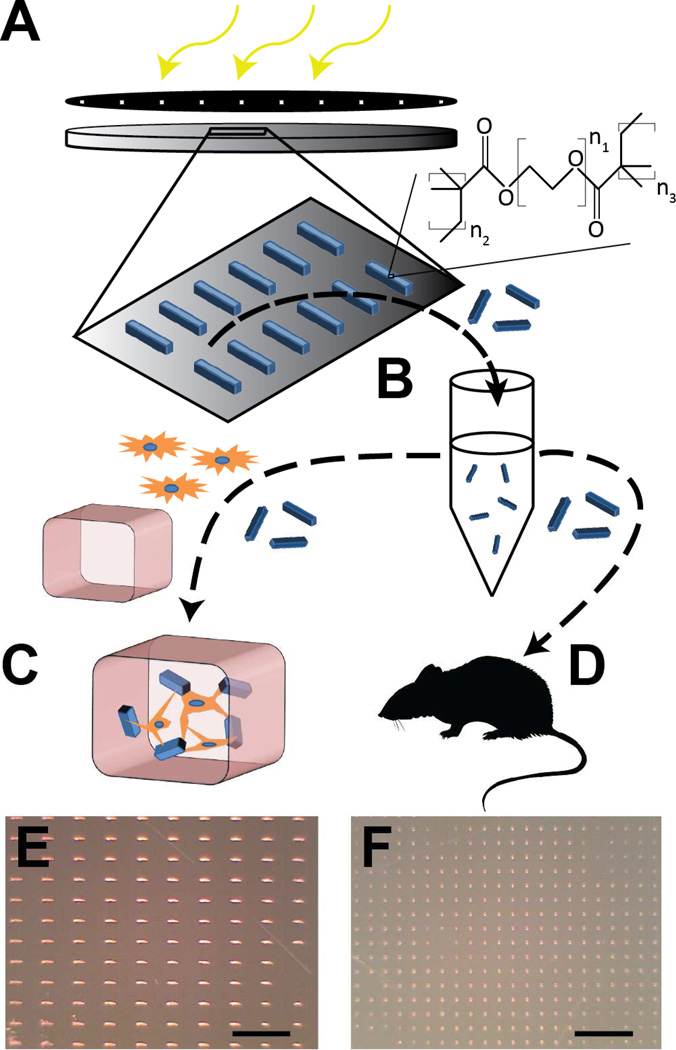

Fig. 1. Microstructure fabrication and experiment design.

Microstructures are fabricated photolithographically by exposure of a thin film of hydrogel polymer to UV energy through a patterned photomask (A). Microrods and microcubes are released from the surface in sterile saline solution (B). From here, the microstructures are either added to a solution of fibroblasts and liquid phase Matrigel to create in vitro 3D tissue constructs for study of cell-microstructure interactions (C), or are injected in saline solution into the infarct zone of Sprague-Dawley rats under ultrasound guidance 48 hours after temporary LAD ligation and reperfusion (D). Light micrographs show high throughput arrays of microrods (E) and microcubes (F) on a silicon wafer. Scale bar = 500 µm.