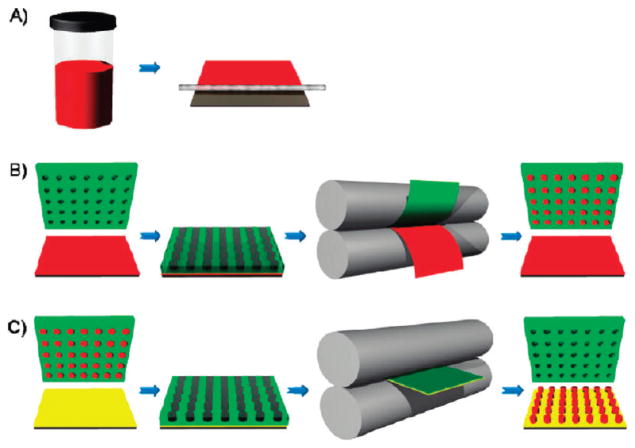

FIGURE 1.

Schematic illustration of the PRINT process. (A) Delivery sheet casting: A true solution (red) is made and then cast on a PET substrate using a mayer rod. Solvent is removed under heat, generating a solid state solution film referred to as the delivery sheet, as it will deliver the composition to the mold. (B) Particle fabrication: a perfluoropolyether elastomeric mold (green) is brought into contact with a delivery sheet (red), passed through a heated nip (gray), and split. The cavities of the mold are filled. (C) Particle harvesting: a filled mold is brought into contact with a high energy film or excipient layer (yellow) and passed through the heated nip without splitting. After cooling, the mold is removed to reveal an array of particles on the high-energy film or excipient layer. Reprinted with permission from ref 43. Copyright 2011 American Chemical Society.