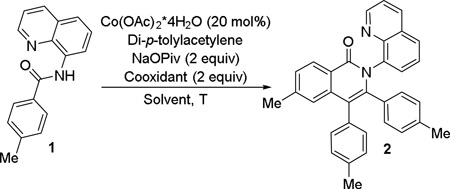

Table 1.

Optimization of Reaction Conditions.[a]

| |||||

|---|---|---|---|---|---|

| Entry | T, °C | Time, h | Solvent | Cooxidant | Ratio 2/1 |

| 1[b,c] | 150 | 12 | DMF | AgOPiv | <1/99 |

| 2[b,c] | 150 | 12 | o-Cl2C6H4 | AgOPiv | 1/2 (33%)[h] |

| 3[b,c] | 150 | 12 | CF3CH2OH | AgOPiv | >99/1 (63%)[h] |

| 4 | 60 | 12 | CF3CH2OH | AgOPiv | >99/1 (65%)[h] |

| 5[b] | 25 | 12 | CF3CH2OH | AgOPiv | 1/4 (16%)[h] |

| 6 | 60 | 12 | CF3CH2OH | K2S2O8 | <1/99 |

| 7[d] | 60 | 2 | CF3CH2OH | PhI(OAc)2 | 1/1 (11%)[h] |

| 8 | 60 | 16 | CF3CH2OH | Mn(OAc)2 | 5/1 (79%)[h] |

| 9[e] | 80 | 2 | CF3CH2OH | Mn(OAc)2 | 1/2 (63%)[h] |

| 10[e,f] | 80 | 12 | CF3CH2OH | Mn(OAc)2 | <1/99 |

| 11[g] | 80 | 18 | CF3CH2OH | O2 | 1/1 (50%)[h] |

| 12[d] | 80 | 2 | CF3CH2OH | Mn(OAc)2 | 10/1 (87%)[h] |

Amide 0.1 mmol, solvent 0.7 mL. Conversions were determined by 1H NMR analysis.

Co(OAc)2 catalyst.

Cooxidant: 0.8 equiv.

Cooxidant: 1 equiv.

Cooxidant: 0.5 equiv.

Deoxygenated solvent.

Reaction vessel pressurized with O2.

NMR yield of 2 using 1,1,2-trichloroethane as internal standard in parentheses.