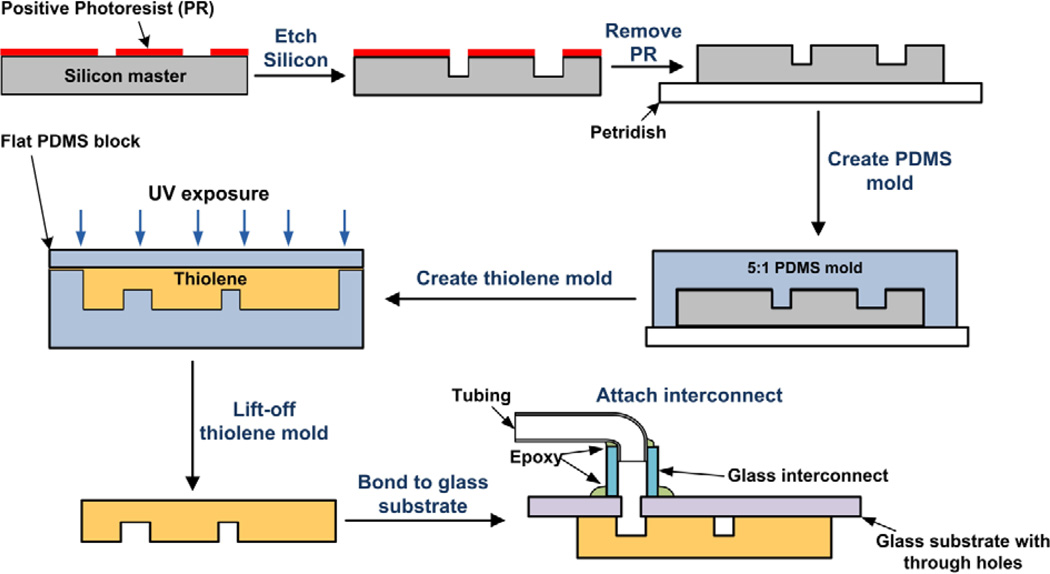

Fig 1.

Fabrication steps for the thiolene-based LLX microfluidic platform. The microfluidic platform pattern is created on a silicon wafer by photolithography and deep reactive ion etching (DRIE), followed by replica-molding to obtain a PDMS mold of the microfluidic platform. This PDMS mold is then used to transfer the pattern of microchannels in thiolene by pouring the liquid pre-polymer and subsequent partial curing via UV exposure. The thiolene mold is then brought in contact with a glass substrate with pre-drilled holes at the inlets and outlets of the microchannels and bonded to the glass by prolonged UV exposure. The glass interconnects and PTFE tubing is then bonded at the inlets and outlets by application of epoxy and subsequent room temperature curing.