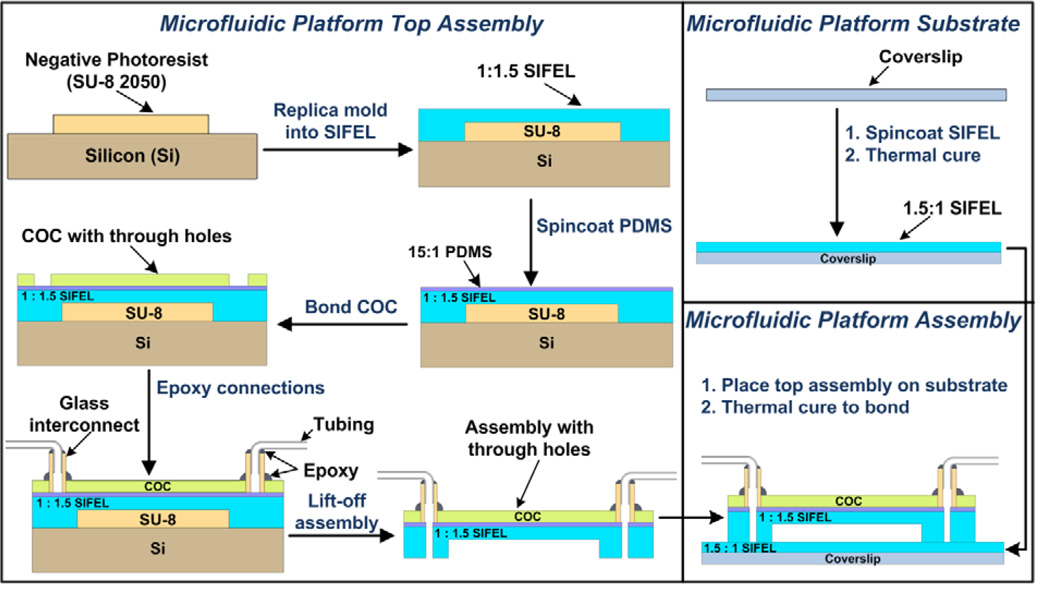

Fig 2.

Fabrication steps for the SIFEL-based LLX microfluidic platform. Negative pattern for the microfluidic platform is created on a silicon wafer by photolithography, which is replicated in SIFEL via soft lithography followed by partial curing. A thin layer of PDMS is then spin-coated on top of the SIFEL layer. A cyclic olefin copolymer (COC) sheet with predrilled holes at the inlets and outlets of the microchannels is irreversibly bonded (plasma) to the top of the PDMS-SIFEL layer. The glass interconnects and PTFE tubing is then bonded at the inlets and outlets by application of epoxy and subsequent room temperature curing. Simultaneously, SIFEL is spin coated on a cover slip and partially cured. Finally, the COC-PDMS-SIFEL assembly is lifted off the master and brought in contact with the cover slip spin coated with SIFEL, followed by thermal curing to irreversibly bond the two layers.